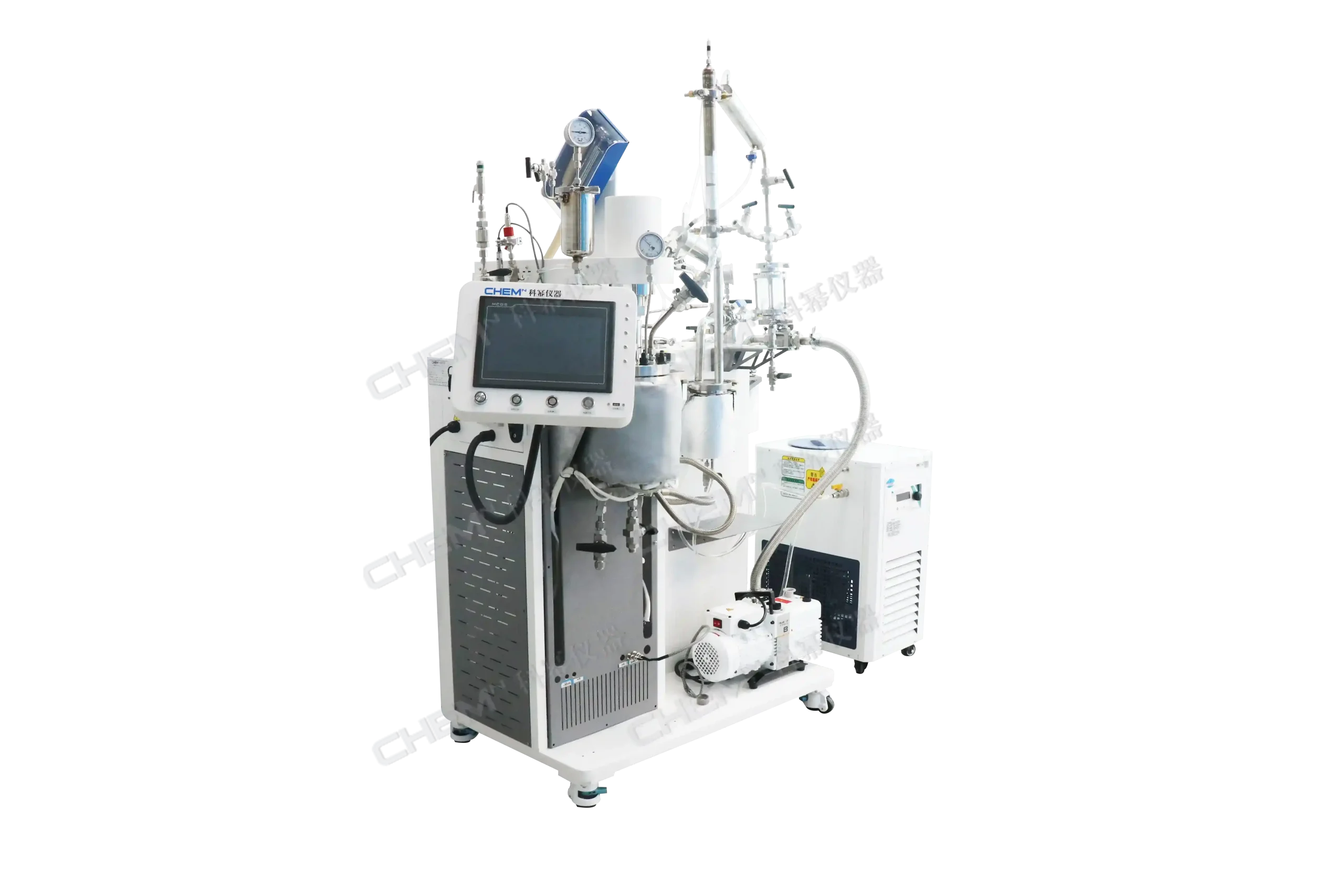

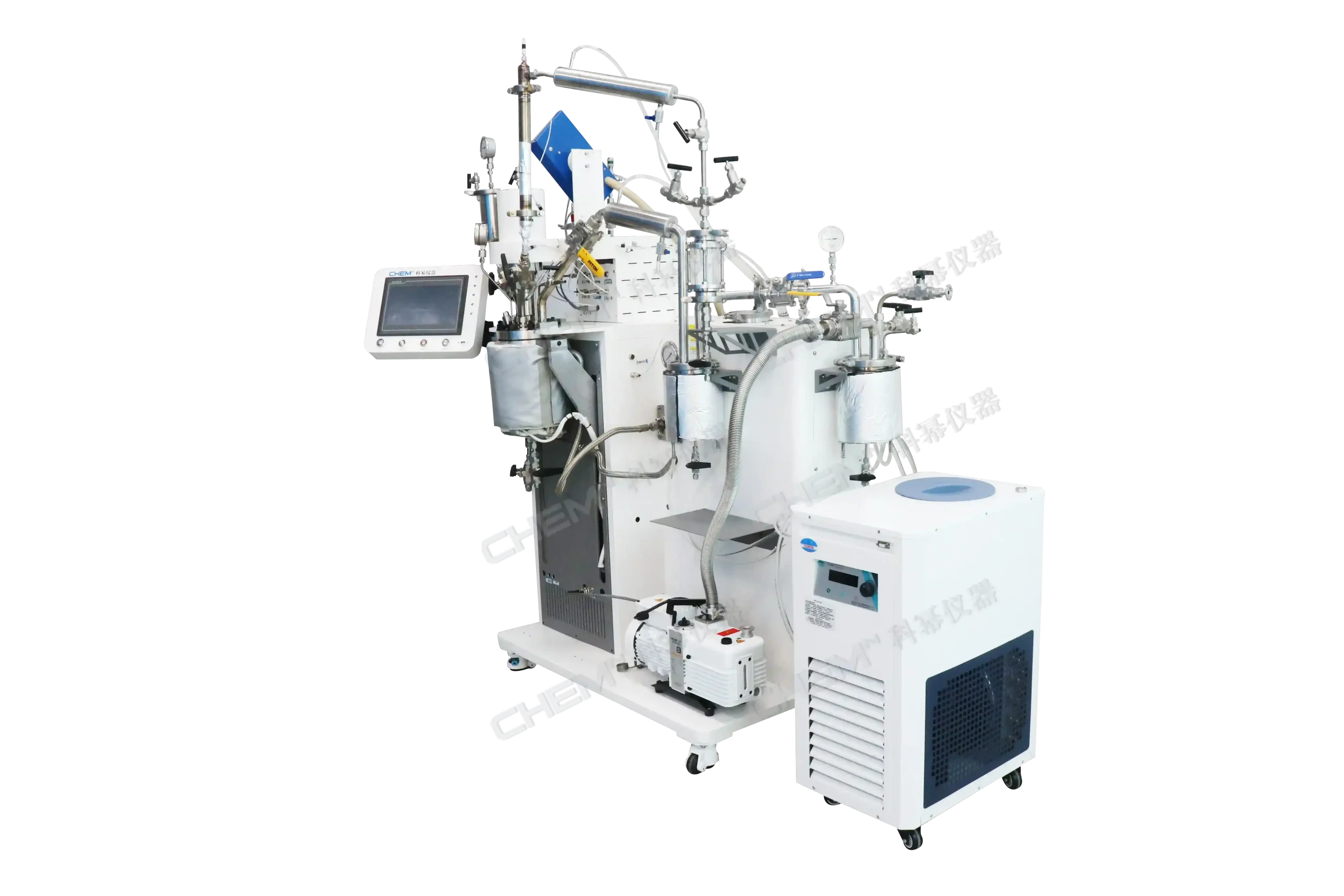

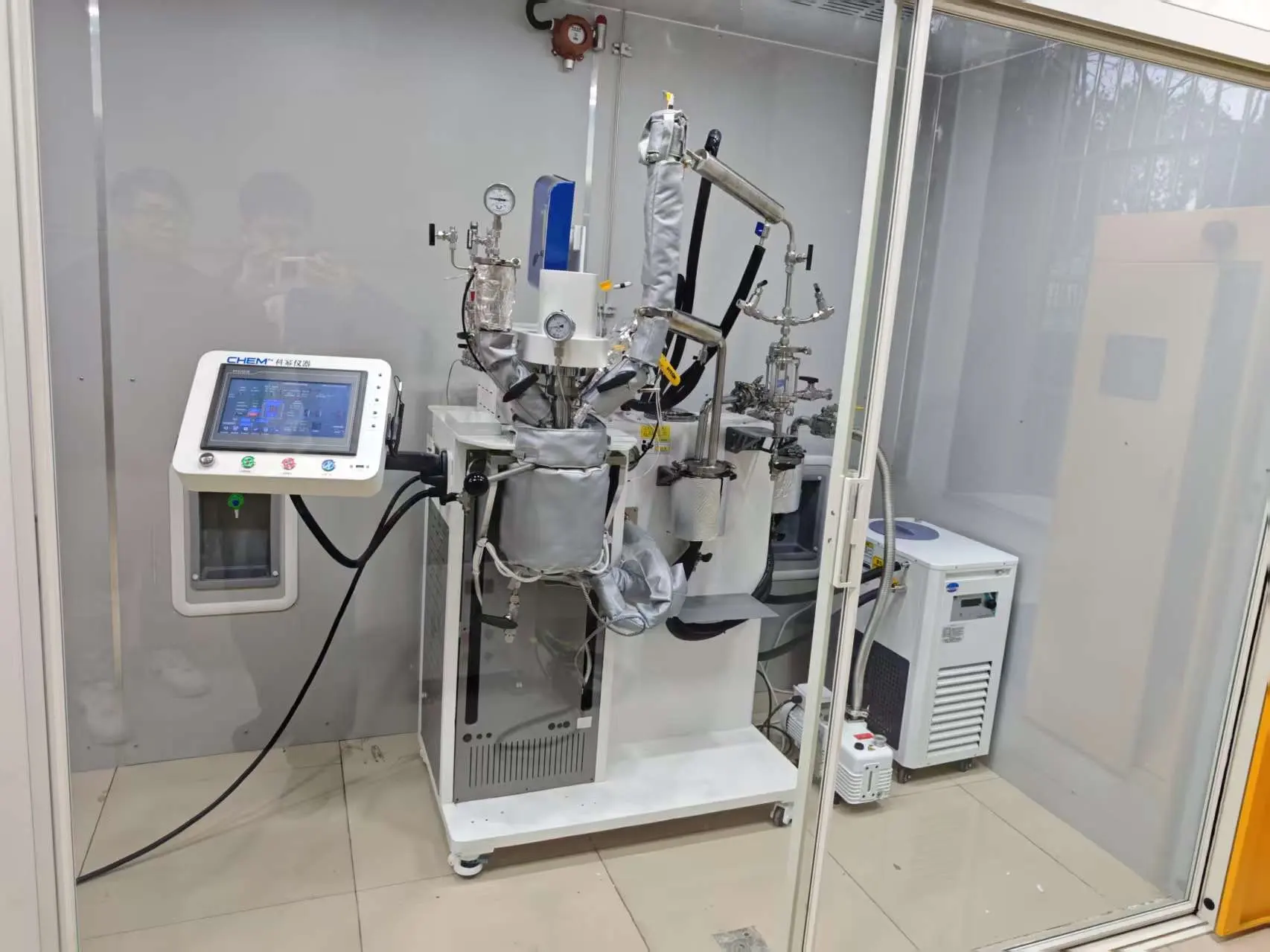

This equipment is a 1L polyester reactor experimental system, equipped with a jacketed polycondensation collection tank and a jacketed vacuum buffer tank. To enhance its applicability in other polyester research directions, it features an esterification pipeline system including an esterification fractionation column, condenser, and glass esterification collection tank. The reactor is designed with a working pressure of 1 MPa and a temperature rating of 310°C. It integrates multiple functions: pressure display, gas inlet/outlet ports, liquid/solid feeding ports, safety protection devices, temperature monitoring, and vacuum level display.

The system employs a high-torque magnetic coupling stirrer delivering 28 N·m torque output via a reducer and belt transmission. Oil bath heating ensures rapid temperature rise while maintaining uniform temperature distribution within the reactor. Equipped with a vacuum pump and vacuum gauge, it achieves precise vacuum control with an ultimate vacuum level of 3 Pa.

A 10.2-inch touchscreen interface with dedicated control software enables real-time monitoring and recording of reactor parameters (temperature, pressure, stirring status, vacuum level). Features include tiered pressure/temperature alarms, process data logging/transmission, historical trend statistics, and remote operation via PC or mobile app.

Design Features

- The kettle cover is fixed, the kettle body is electrically lifted and lowered, and the position is automatically limited. It is equipped with a liquid feeding tank and a solid feeding port, which is convenient for feeding and cleaning;

- 3kW oil bath heating, up to 310℃, rapid heating, and balanced temperature field;

- High-torque magnetic coupling stirrer, stable stirring, real-time recording of stirring torque;

- It is equipped with a discharge plug and a discharge ball valve, suitable for different working conditions;

- Equipped with a Dixon mesh ring 2mm filler inside the esterification fractionation tower;

- Intelligent display operation, temperature and pressure monitoring, historical data download, more convenient and efficient;

- Computer-side remote control function.

Technical parameters

| Volume | 1L |

| Design pressure | 1MPa |

| Design temperature | 310℃ |

| Operating temperature | 300℃ |

| Material of kettle body and kettle head | 316L |

| Inlet and exhaust valve | FITOK inlet and outlet needle valve |

| Safety valve | FITOK safety valve |

| Explosion-proof valve | Shanghai Xitai explosion valve |

| Pressure measuring element | American Ashcroft pressure gauge, American MEAS pressure sensor |

| Heating method | High-temperature thermal oil circulation system heating |

| Stirring method | Mechanical stirring |

| Stirring speed | 0-300r/min stepless adjustment |

| Control method | 10.2-inch touch screen displays temperature, speed, working time, etc. |

| Discharging structure | FITOK needle valve |

| Other safety designs | Over-temperature alarm, over-pressure alarm |

| Power supply | AC220V Maximum power 7.5kW |

| Dimensions | 1003*685*1790mm (length*width*height) |

Any requirements, please contact with us. We will try to make it.