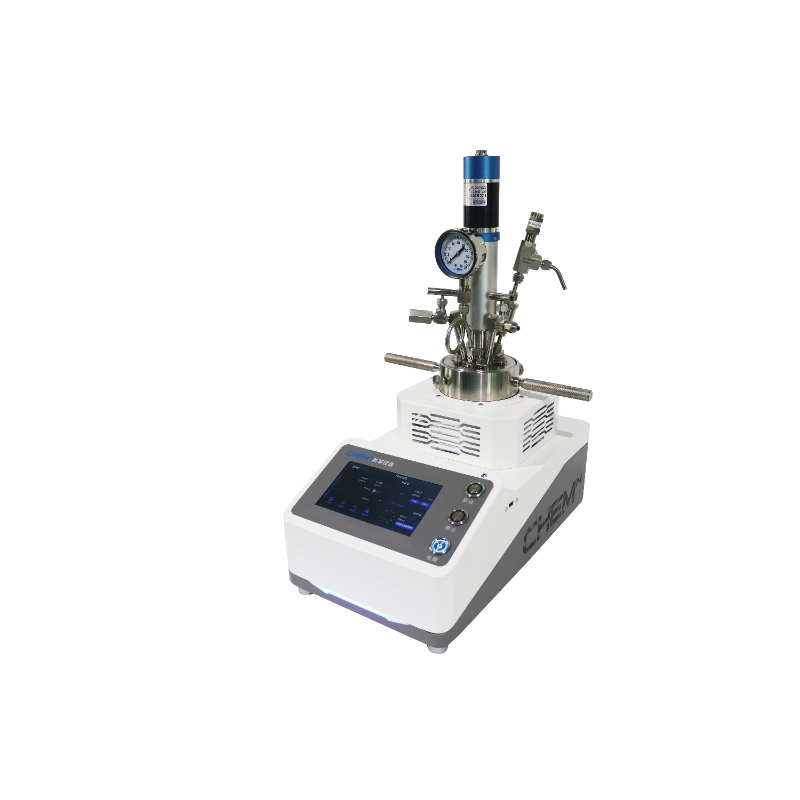

Technical Parameters

| Model | MS★-P5-T3-SS1-SV-R-2/4/6 |

| Design volume | 25 mL, 50 mL, 100 mL, 300 mL, 500 mL |

| Design temperature | Standard 300 ℃ |

| Design pressure | Standard 207 bar (optional) |

| Heating mode | Embedded stainless steel heating module |

| Heating power | 1 kW |

| Stirring speed | 100-1200 rpm (stepless speed regulation) |

| Stirring method | High-torque magnetic coupling stirring |

| Material of reactor | 316 L stainless steel, Hastelloy C-276,etc.(optional) |

| Intelligent Micro Reactor Controller | Over-temperature automatic power-off, over-pressure buzzer alarm 7-inch touch screen, displaying the temperature, rotation speed, pressure and operating time USB interface, supporting data export Power supply configuration: 200 – 240 V/AC, 50 – 60 Hz Outline dimension: about 250*460*410 mm |

| Pressure sensor | MEAS |

| Pressure gauge | WIKA |

| Inlet/Outlet valves | Fitok/Swagelok |

| Personalized options | Various alloy materials, stirring forms, sampling and cooling, etc.optional configurations |

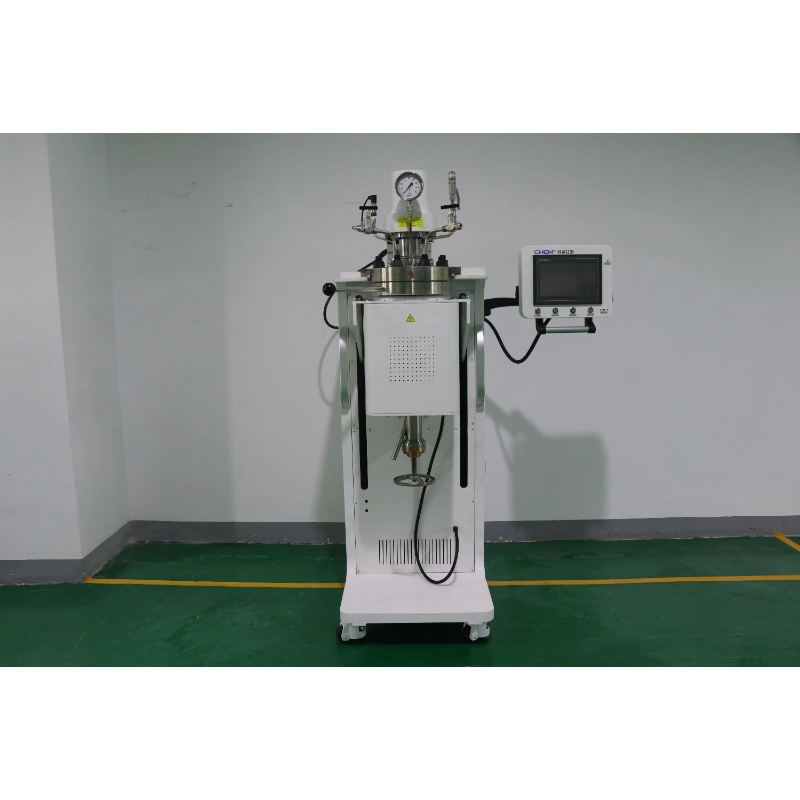

The Selection of Kemi reactor could be based on the following four basic parameters.

(1) Maximum working pressure

The design working pressure is 207bar for reactor < 500ml, 103bar for Photocatalysis reactor. Kemi produce the reactor whose maximum working pressure is 345bar. Kemi could also produce customized reactor according to different requirements.

(2) Maximum operating temperature

The design operating temperature of the conventional reactor is 300℃ (sealed with reinforced PTFE flat gasket) and maximum temperature is 550℃ (sealed with Grafoil graphite gasket), the operating temperature can be adjusted according to customer requirements.

(3) Capacity selection

The capacity of Kemi reactor ranges from 10ml to 29L. The volume here refers to the maximum volume of the reactor, Generally, the liquids should not exceed 2/3 of the volume of the reactor.

(4) Material selection

The material of Kemi regular reactor is 316L stainless steel and Hastelloy C-276, and other materials are also available:

– Industrial Titanium TA2

– Zirconium alloys 702, 705

– Other required metal materials

Kemi Reactors and Pressure vessels could meet most demands of chemical experiments for high temperatures and pressures reaction environments.

Different design solutions can be provided according to different requirements. Kemi will provide conventional configuration if there was no special requirements. For special requirements, please communicate with us and our technician can give you good solution.

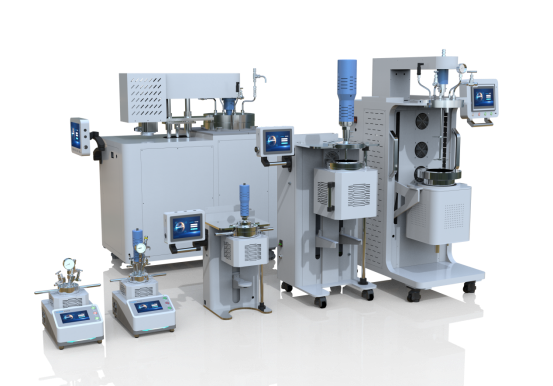

UPDATED TYPE

Independently controlled functions, gas distribution panel, capable of parallel reactions or independent high-throughput experiments. Suitable for rapid catalyst screening, reaction condition optimization, and parallel experiments with trace samples.

COMPANY INTRODUCTION

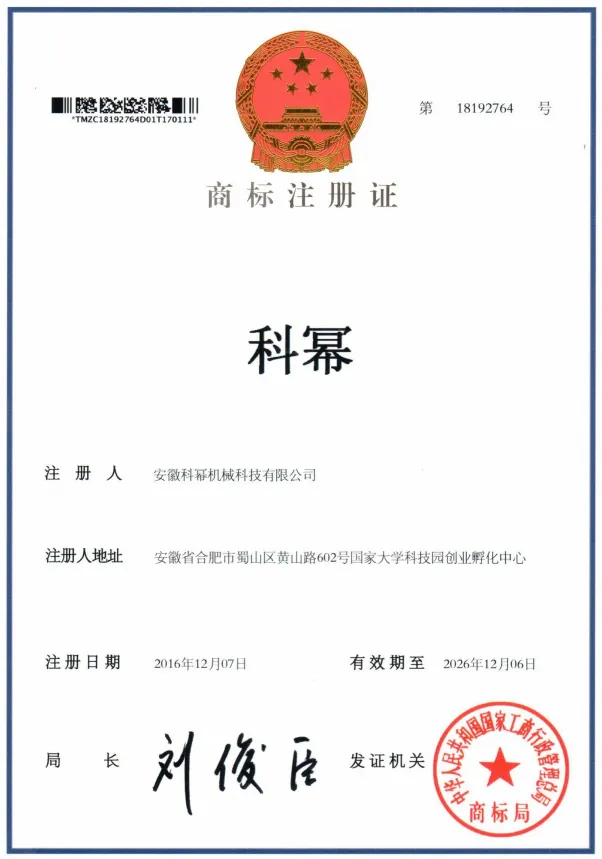

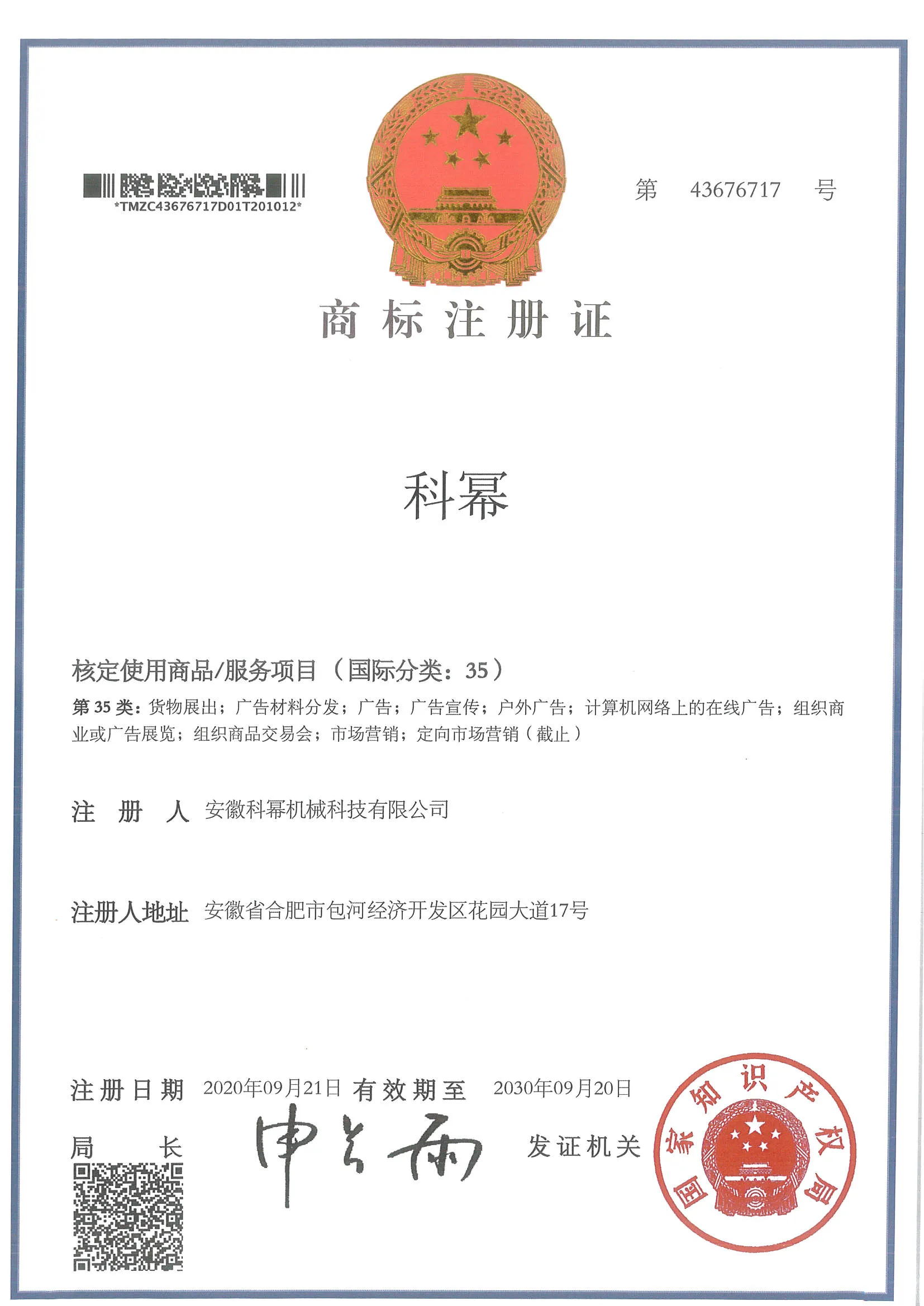

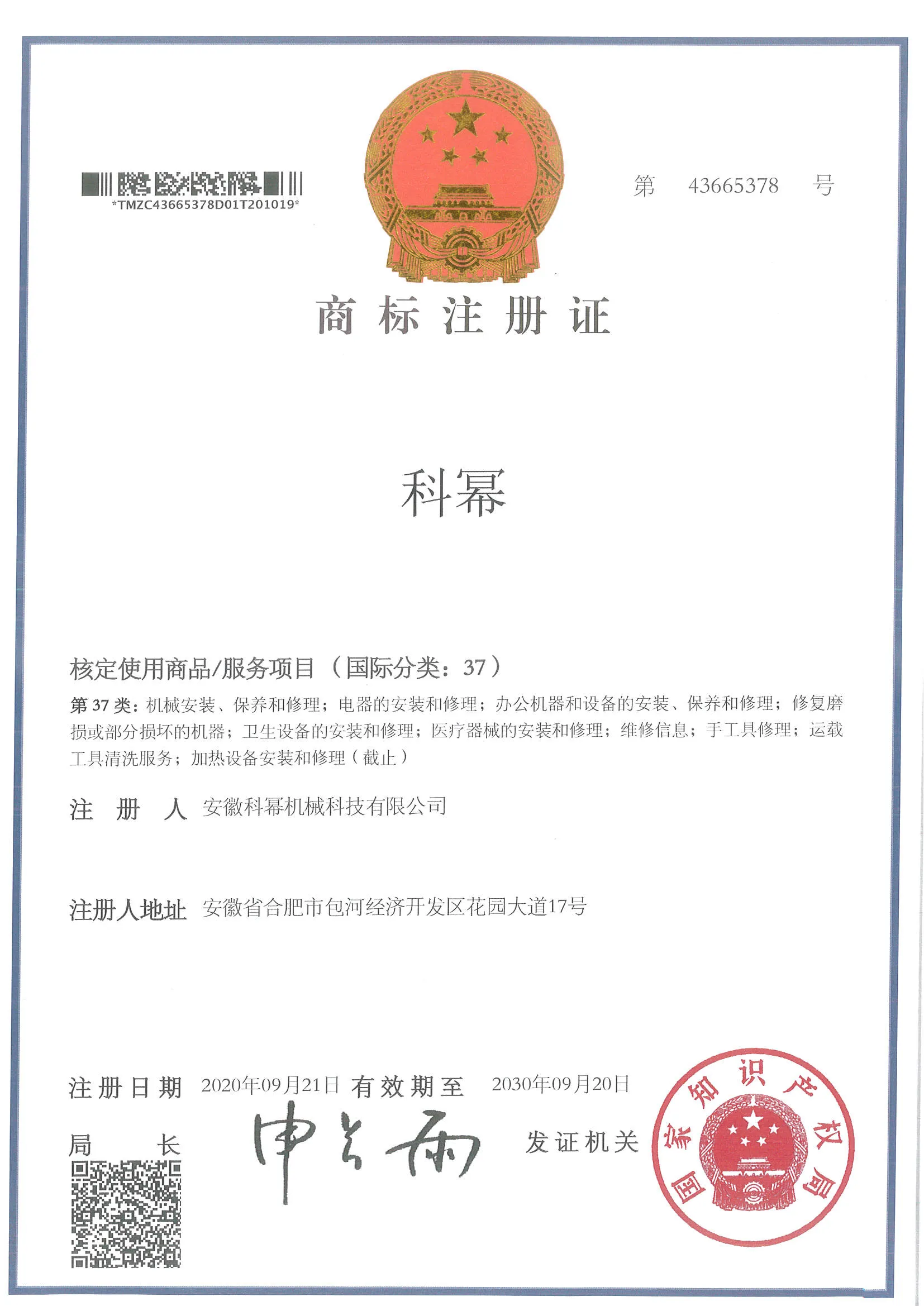

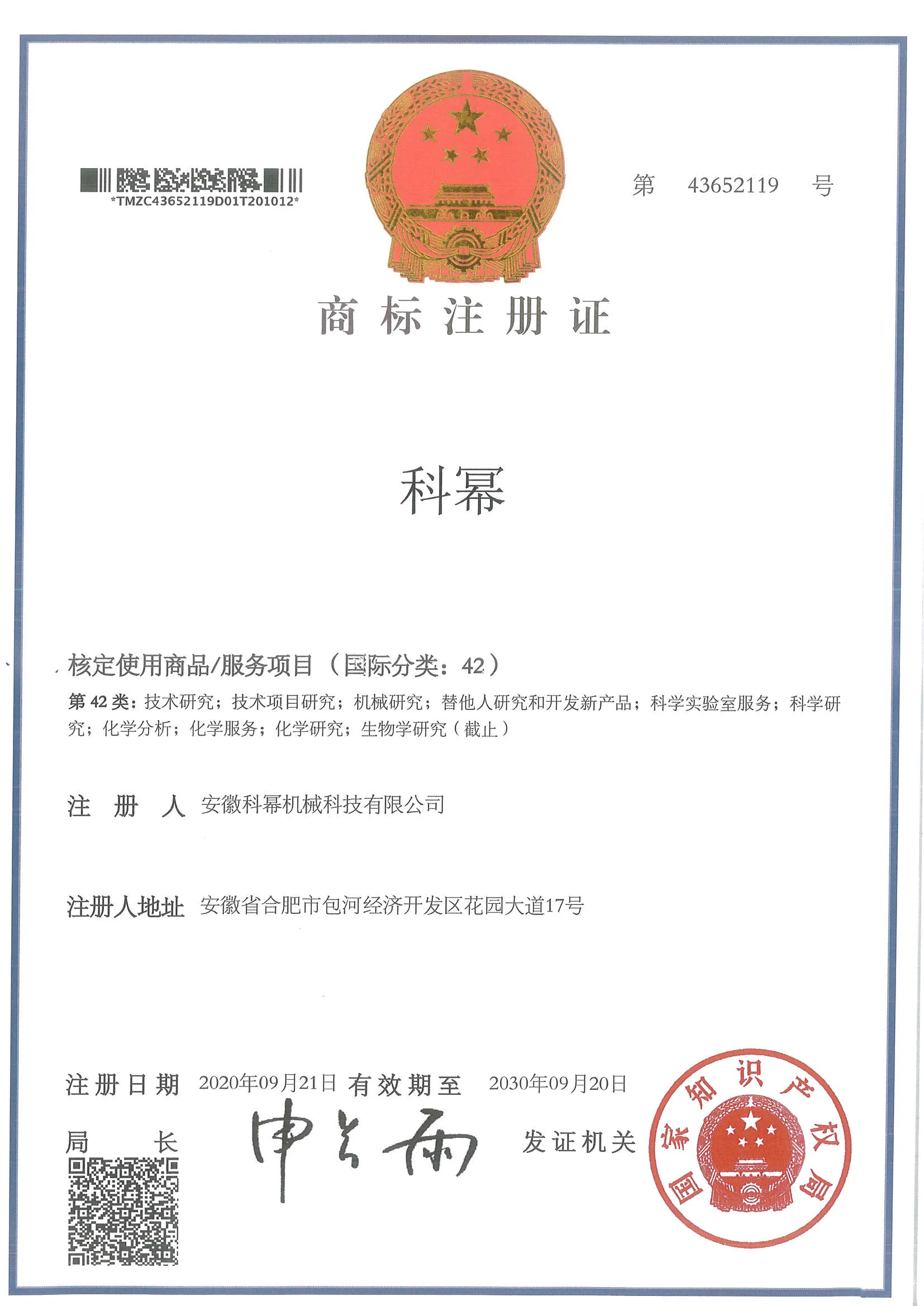

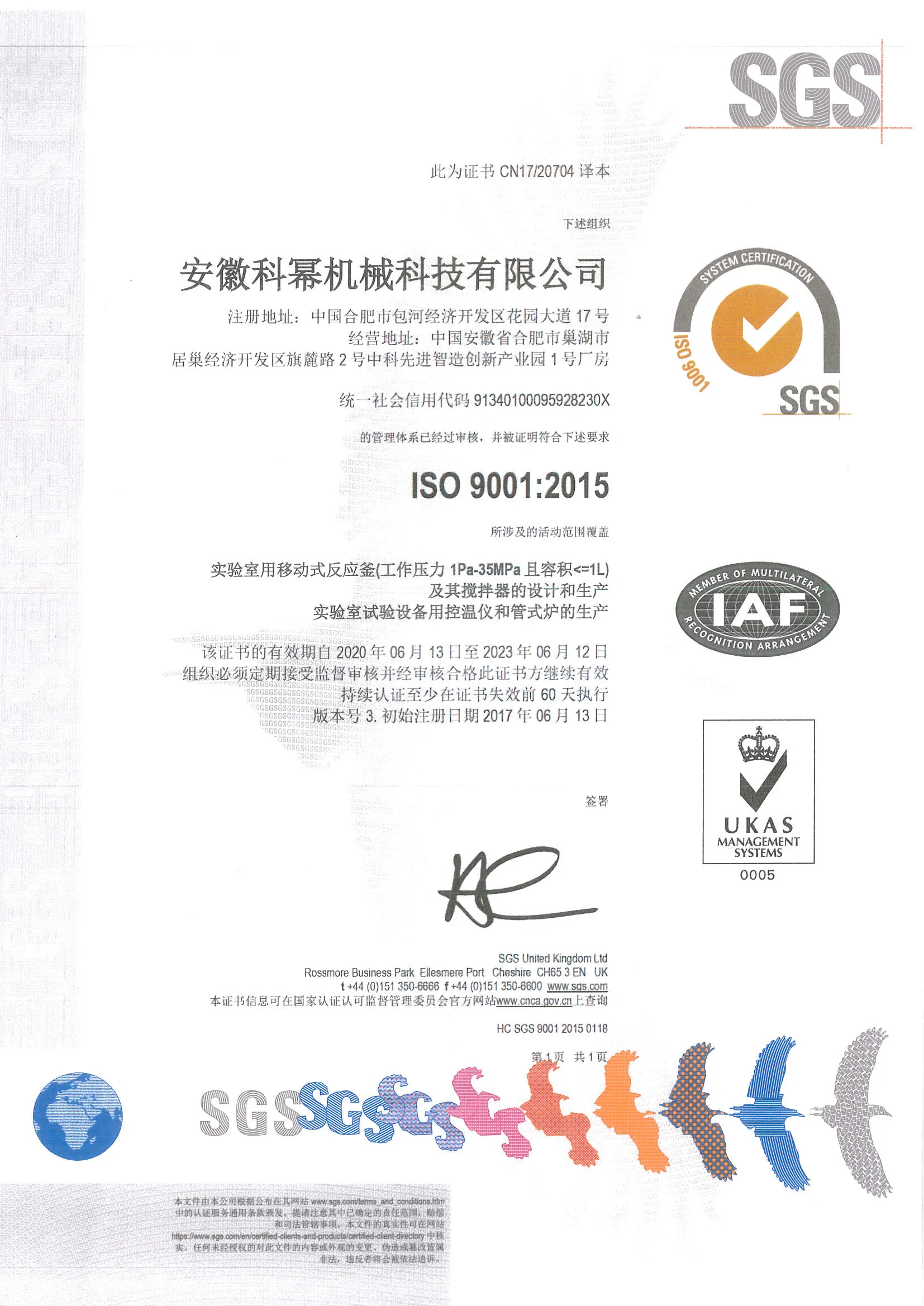

Anhui Kemi Instrument Co. Ltd was founded by a creative team from University of Science and Technology of China (USTC)in 2014, aiming to design and provide high-quality and customized synthesis equipment for global R&D users.We have SGS, ISO9001 and CE certificates. Our company is committed to design and provide “safe, convenient, accurate and efficient” equipment, and accelerate R&D progress with our professionalism and quality. Up to 2025, we have over 300 clients from over 35 countries, and our products have helped R&D users to publish over 900 papers in top-tier journals.

WHY CHOOSE US ?

In a global marketplace filled with choices, we stand out as a reliable and innovative partner for your business needs. Our commitment to quality, efficiency, and customer satisfaction has made us the preferred choice for clients worldwide.

Adhere to strict international quality standards (ISO/CE certified). Each product undergoes 12 inspection processes to ensure zero defects.

With over 12 years in the industry, we’ve served 20000+ clients across 30+ countries, providing customized solutions for diverse needs.

Direct factory supply cuts out middlemen, offering you competitive prices with 10-15% savings compared to the market average.

Benefit from our efficient supply chain—80% of orders are delivered within 15 days, even for large volumes.

24/7 multilingual support (English, Spanish, Mandarin) and a dedicated account manager ensure seamless communication from inquiry to after-sales.

Our R&D team, consisting of 50+ experts, launches 10+ new products annually, keeping you ahead of market trends.