Table of Contents

Tube furnaces, as one of the key pieces of equipment for high-temperature experiments in laboratories, are widely used in material synthesis, heat treatment, chemical vapor deposition, and other fields. The versatility in design and functionality allows tube furnaces to meet the needs of various experiments. This article will provide a detailed introduction to the common types, application areas, price ranges, as well as cleaning and maintenance considerations for tube furnaces.

Tube Furnace Common Types

According to experimental requirements and operation methods, laboratory tube furnaces can be divided into four common types: horizontal tube furnaces, vertical tube furnaces, rotary tube furnaces, and multi-temperature zone tube furnaces.

Horizontal Tube Furnace: The horizontal tube furnace is the most commonly used type in laboratories. The furnace tube is placed horizontally, making it easy to load and remove samples. It is suitable for most experiments requiring stable heating. This design makes operation simpler while ensuring uniform heating of the samples.

Vertical Tube Furnace: The vertical tube furnace has the furnace tube placed vertically. It is mainly used for experiments that require the influence of gravity, such as the growth of certain crystals or powder deposition. Due to its vertical design, the sample is more affected by gravity, making it suitable for specific research needs.

Rotary Tube Furnace: The furnace tube in a rotary tube furnace can rotate slowly. This feature is particularly useful for continuous processing of powders, particles, or bulk samples. The rotation ensures more even heating of the samples and prevents clumping or aggregation.

Multi-zone Tube Furnace: A multi-zone tube furnace has several independent heating zones that allow different temperature settings within the same furnace tube. This design is particularly important for experiments that require precise temperature control, such as Chemical Vapor Deposition (CVD), where temperature gradient control is essential.

Main Applications of Tube Furnaces

Due to their ability to provide precise temperature control and adjustable atmosphere environments (such as vacuum, inert gases, or reactive gases), tube furnaces are widely applied in various fields:

Material Synthesis and Preparation: Tube furnaces are used for synthesizing various advanced materials, such as carbon nanotubes, graphene, semiconductor materials, ceramics, and polymers. They provide a stable high-temperature environment for the synthesis of these materials.

Heat Treatment: In processes such as annealing, sintering, quenching, and tempering of metals and ceramics, tube furnaces offer precise temperature control, effectively improving the physical properties of materials.

Chemical Vapor Deposition (CVD): Tube furnaces are crucial for thin film and coating preparation. By heating reactive gases and allowing them to deposit on a substrate, tube furnaces are widely used in the manufacturing of semiconductors, optical coatings, and wear-resistant coatings.

Catalytic Reaction Research: Tube furnaces provide the controlled temperature and atmosphere conditions necessary for catalytic reaction research, allowing the testing of catalyst performance and reaction mechanisms.

Pyrolysis and Reduction Reactions: Tube furnaces are used for high-temperature pyrolysis to decompose materials or reduce metal oxides in a reducing atmosphere, thereby extracting metals. These processes are important in chemical, metallurgical, and other fields.

Price Range of Tube Furnaces

The price of tube furnace varies based on its type, temperature range, number of temperature zones, and customization requirements. The following are typical price ranges:

Entry-level/Basic Model (Single Temperature Zone, Max 1100℃): Prices generally range from $2,000 to $5,000, suitable for general heating needs.

Mid to High-end Model (Multi-zone, Max 1400℃ or higher): Prices typically range from $5,000 to $15,000, suitable for more complex experiments and offering more precise temperature control.

High-end Customized Model (Ultra-high Temperature, Vacuum, Rotation, etc.): Prices usually exceed $15,000, and may be higher depending on the complexity of the requirements. These models typically feature special custom functions such as ultra-high temperature heating, vacuum control, or rotation.

Cleaning and Maintenance of Tube Furnaces

Proper cleaning and maintenance are crucial for prolonging the lifespan of a tube furnace and ensuring accurate experimental results. The following are some common cleaning and maintenance tips:

- Cooling and Power Off: Before cleaning and maintenance, ensure that the tube furnace has cooled down to room temperature. Always disconnect the power supply to ensure safety.

- Cleaning the Furnace Tube: Regularly check the furnace tube for residual materials. If there are solid residues, use a soft brush or non-metallic tools to remove them. For organic residues, use acetone or ethanol for wiping, followed by thorough rinsing and drying. For stubborn residues, high-temperature firing can be used to remove them, but care should be taken not to damage the tube or generate harmful gases.

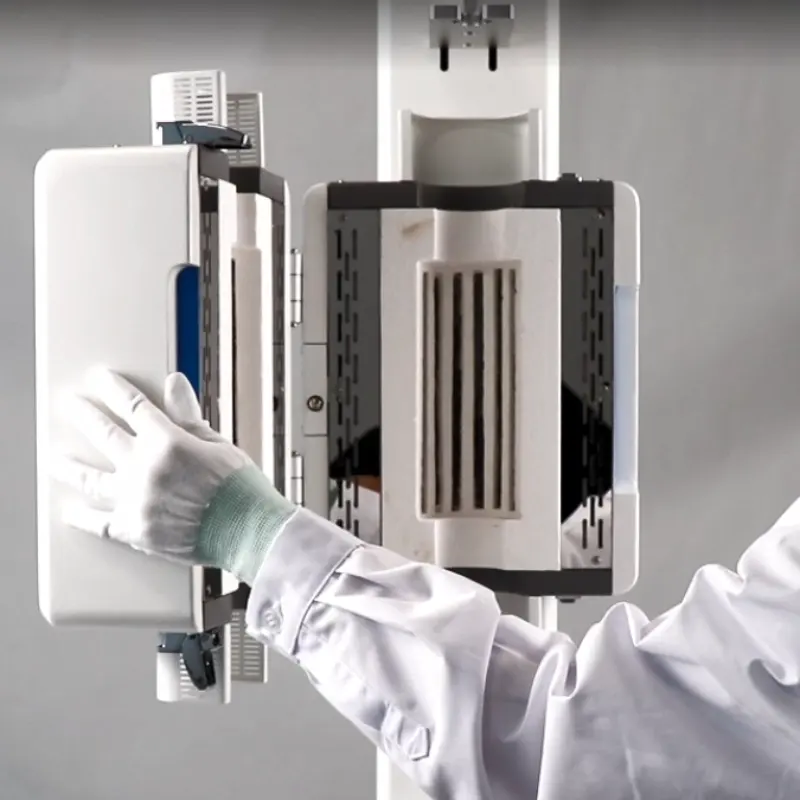

- Sealing Component Maintenance: Regularly inspect the seals at both ends of the furnace tube (e.g., O-rings and flanges). If any aging, cracks, or hardening is detected, replace them in a timely manner. Lubricating the seals with high-temperature lubricants can help extend their lifespan.

- Heating Element Maintenance: Keep the furnace chamber dry to prevent moisture ingress. Heating elements are fragile and should be protected from impacts. Regularly inspect their condition and replace them promptly if any issues arise.

- Daily Usage Practices: Avoid sudden temperature changes during operation. Gradually increase and decrease the temperature. Ensure that samples are placed evenly to avoid local overheating.

Conclusion

Tube furnaces are indispensable in modern laboratories. Their wide range of applications and diverse functions make them the preferred tool for high-temperature experiments. From material synthesis to heat treatment, from chemical vapor deposition to catalytic reaction research, tube furnaces play a crucial role. With proper cleaning and maintenance, tube furnaces can maintain stable performance over the long term, providing reliable support for experiments.

About the Author

Anhui Kemi Instrument Co., Ltd., founded in 2014, is headquartered in Hefei Economic and Technological Development Zone with a 10,000 sqm R&D and manufacturing base. The company holds an A2-level China special equipment production qualification for pressure vessels. Specializing in scientific research equipment, Kemi has served over 20,000 research institutions worldwide, including all “985” and “211” universities in China, and exported products to Europe, the U.S., Australia, and the Middle East. Kemi focuses on providing customized experimental equipment, non-standard solutions, and multidimensional services. We use high-quality parts from renowned suppliers like Swagelok, IKA, MEAS, and Omega®, ensuring product reliability. Committed to delivering “safe, convenient, accurate, and efficient” instruments, we aim to assist clients in publishing 2,000 top international papers and achieving 1,000 application results in the next five years.

Click to learn more about our tube furnace products: High Temperature Furnaces – Kemi