Applied Catalysis B: Environment and Energy

First author: Cheng Miao, Pan Shaoqing

Corresponding author: Liu Bo

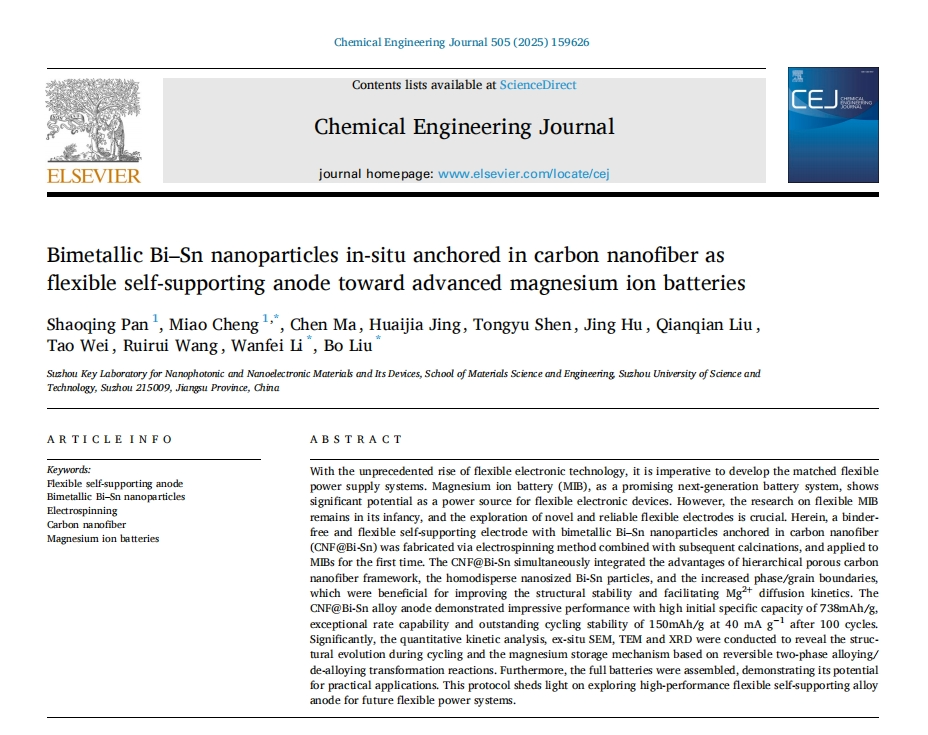

Article title: “Bimetallic Bi–Sn nanoparticles in-situ anchored in carbon nanofiber as flexible self-supporting anode toward advanced magnesium ion batteries”

Impact factor: 13.4

Article link: https://doi.org/10.1016/j.cej.2025.159626

Research background

With the booming development of flexible electronic devices, it is increasingly critical to explore and develop high-performance flexible energy storage systems. Among them, flexible lithium-ion batteries have made significant progress in the practical applications of flexible electronics and wearable devices. However, the high cost caused by limited lithium resources and the safety risks caused by uncontrollable lithium dendrite formation pose challenges to their further development and application. Therefore, there is an urgent need to develop alternative battery systems with high natural abundance, low cost and high safety. Rechargeable magnesium-ion batteries are expected to become a reliable alternative to lithium-based battery systems because magnesium resources are abundant and low-cost, have high theoretical specific capacity, have a suitable reduction potential, do not form dendrites during electrochemical deposition/dissolution, and have high operational safety. However, there are very few studies on flexible electrode materials for magnesium-ion batteries. In recent years, electrospinning has been recognized as one of the most convenient, cost-effective and industry-feasible technologies for manufacturing 3D porous membranes, and more and more researchers are focusing on using electrospun nanofiber-based composites as flexible electrodes.

Paper highlights/abstract

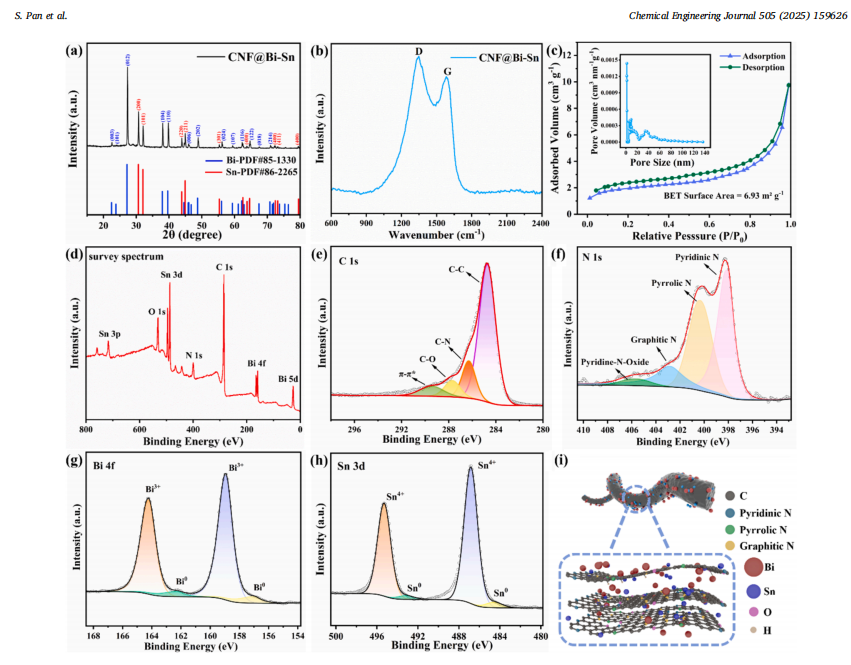

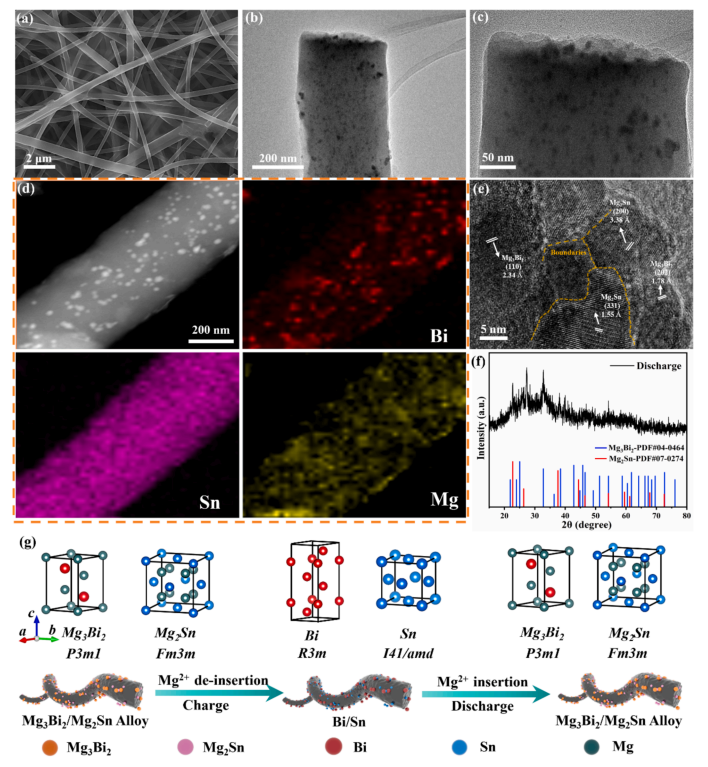

With the unprecedented development of flexible electronic technology, it is imperative to develop a flexible power supply system to match it. As a promising next-generation battery system, magnesium-ion batteries (MIBs) show great potential as a power source for flexible electronic devices. However, the research on flexible magnesium-ion batteries is still in its infancy, and it is crucial to explore new and reliable flexible electrodes. In this paper, a binder-free and flexible self-supporting electrode composed of bimetallic Bi-Sn nanoparticles anchored in carbon nanofibers (CNF@Bi-Sn) was prepared by electrospinning combined with an in-situ thermal reduction process and applied to magnesium-ion batteries for the first time. CNF@Bi-Sn simultaneously integrates the advantages of a multi-level porous carbon nanofiber framework, uniformly dispersed nanoscale Bi-Sn particles, and increased phase/grain boundaries, which help to improve the structural stability of flexible electrode materials and promote the diffusion kinetics of Mg2+. The CNF@Bi-Sn alloy anode exhibits excellent electrochemical performance, a high initial specific capacity of 738 mAh g−1, excellent rate performance and cycling stability, and maintains a reversible capacity of 150 mAh g−1 after 100 cycles at a current density of 40 mA g−1. This work reveals the structural evolution of the flexible electrode material during the cycle and the magnesium storage mechanism based on the reversible two-phase alloying/de-alloying transformation reaction through quantitative kinetic analysis, ex situ SEM, TEM and XRD. In addition, a full battery was assembled to demonstrate its potential in practical applications. This study provides new ideas for exploring and developing flexible self-supporting alloy anodes with high performance.

The mini tube furnace used by Professor Liu Bo’s research group in the experiment was provided by Kemi Instrument. Anhui Kemi Instrument Co., Ltd. was also specifically mentioned in the paper. We would like to express our sincere gratitude to the professor for his choice and recognition of Kemi Instrument.