Technical parameters

| Model | TFV-1200-50-I-220 |

| Body structure | 1. Flange support platforms are designed at the top and bottom of the body 2. The body is designed as open type for easy replacement of the tube 3. The chamber is made of high purity alumina |

| Maximum temperature | 1200 ℃ (short-term) |

| Rated temperature | 1,100 ℃ |

| Thermocouple | K-type thermocouple |

| Adaptive power | AC220 V 50/60 HZ |

| Rated power | 1.5 kW |

| Size of furnace tube | Φ30*550 mm/Φ50*550 mm |

| Heating zone length | 220 mm |

| Heating element | Molybdenum doped aludirome |

| Temperature control system | PID automatic temperature control system Intelligent control through 30 programmable segments |

| Temperature control precision | ±1 ℃ |

| Outline dimension | 340*300*1200 mm |

| Net weight | 45kg |

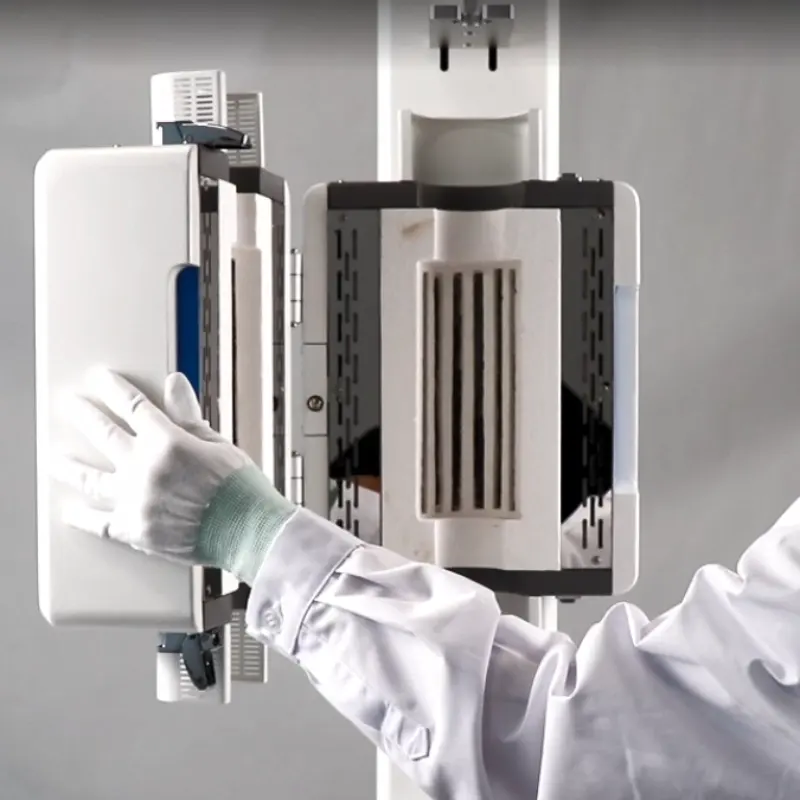

Body structure

Flange support platforms are designed at the top and bottom of the body

The body is designed as open type for easy replacement of the tube

The chamber is made of high purity alumina

Temperature control system

PID automatic temperature control system

Intelligent control through 30 programmable segments

English version is available

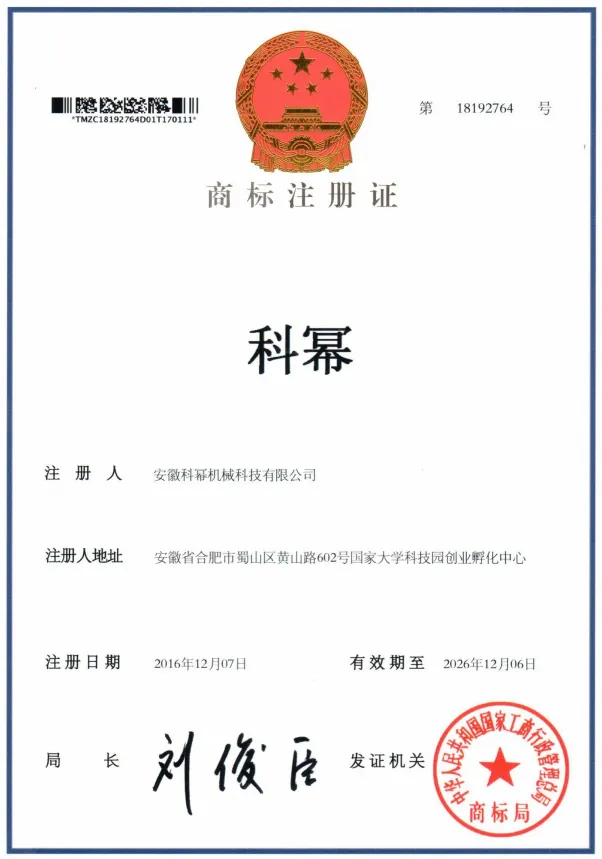

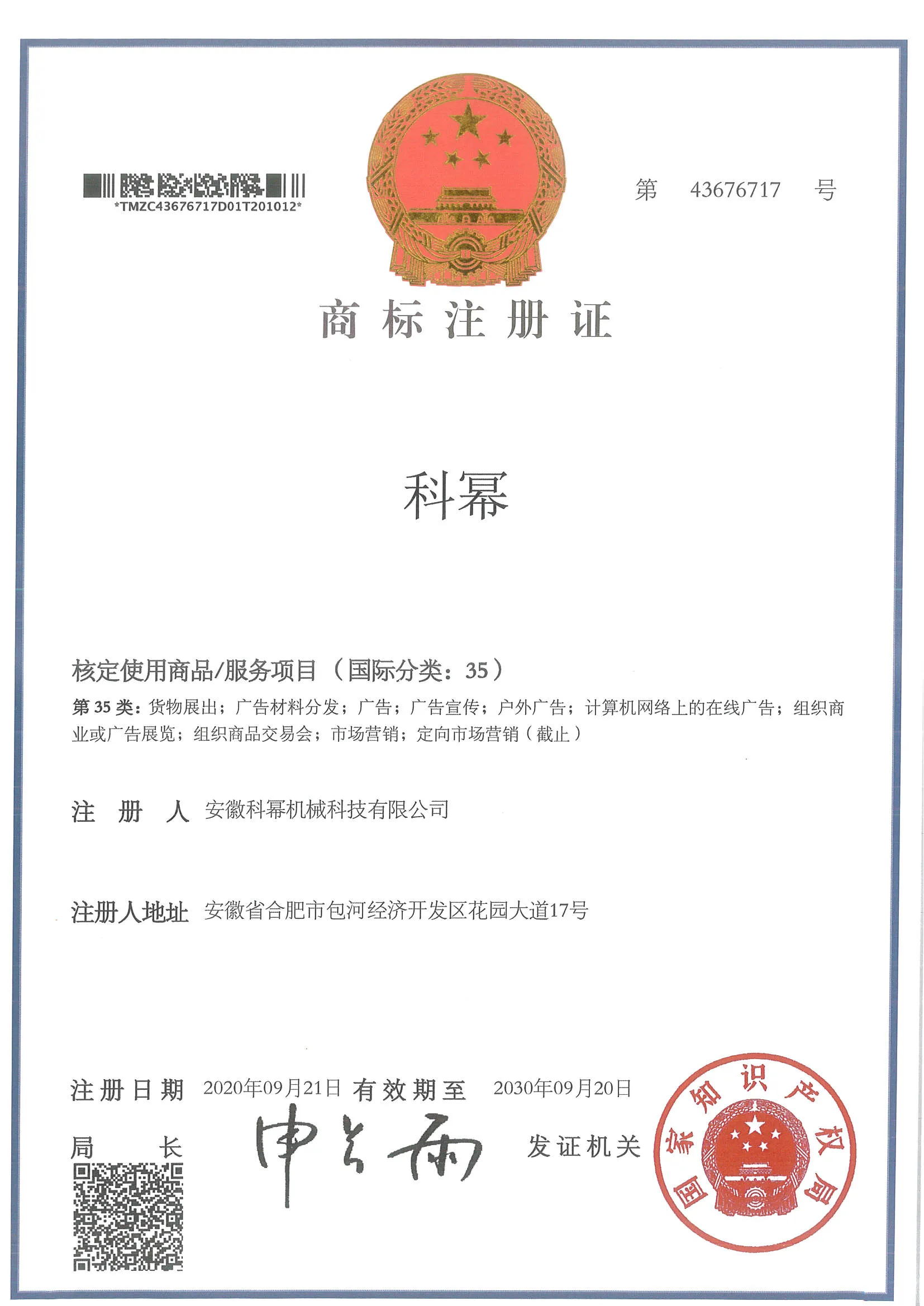

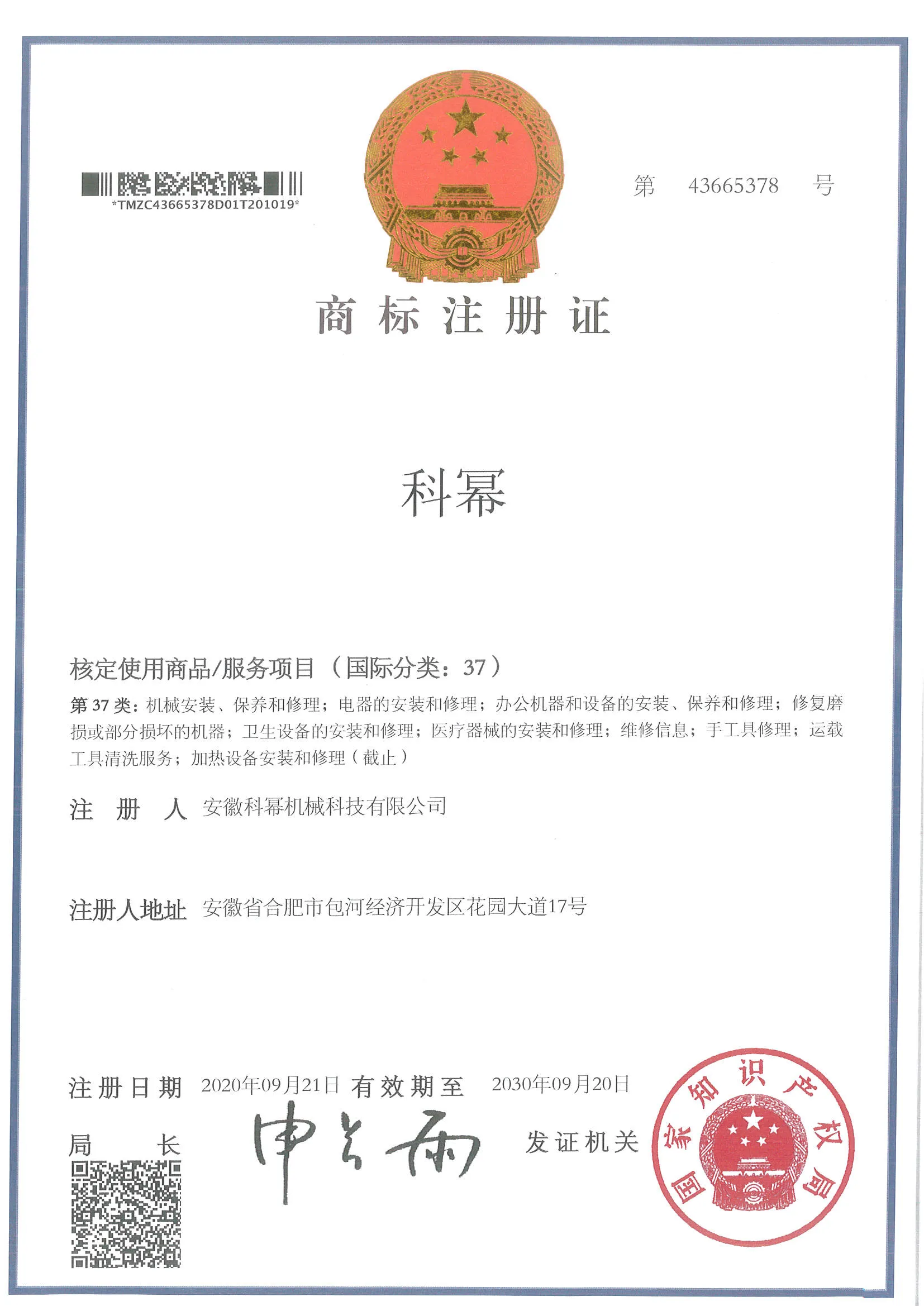

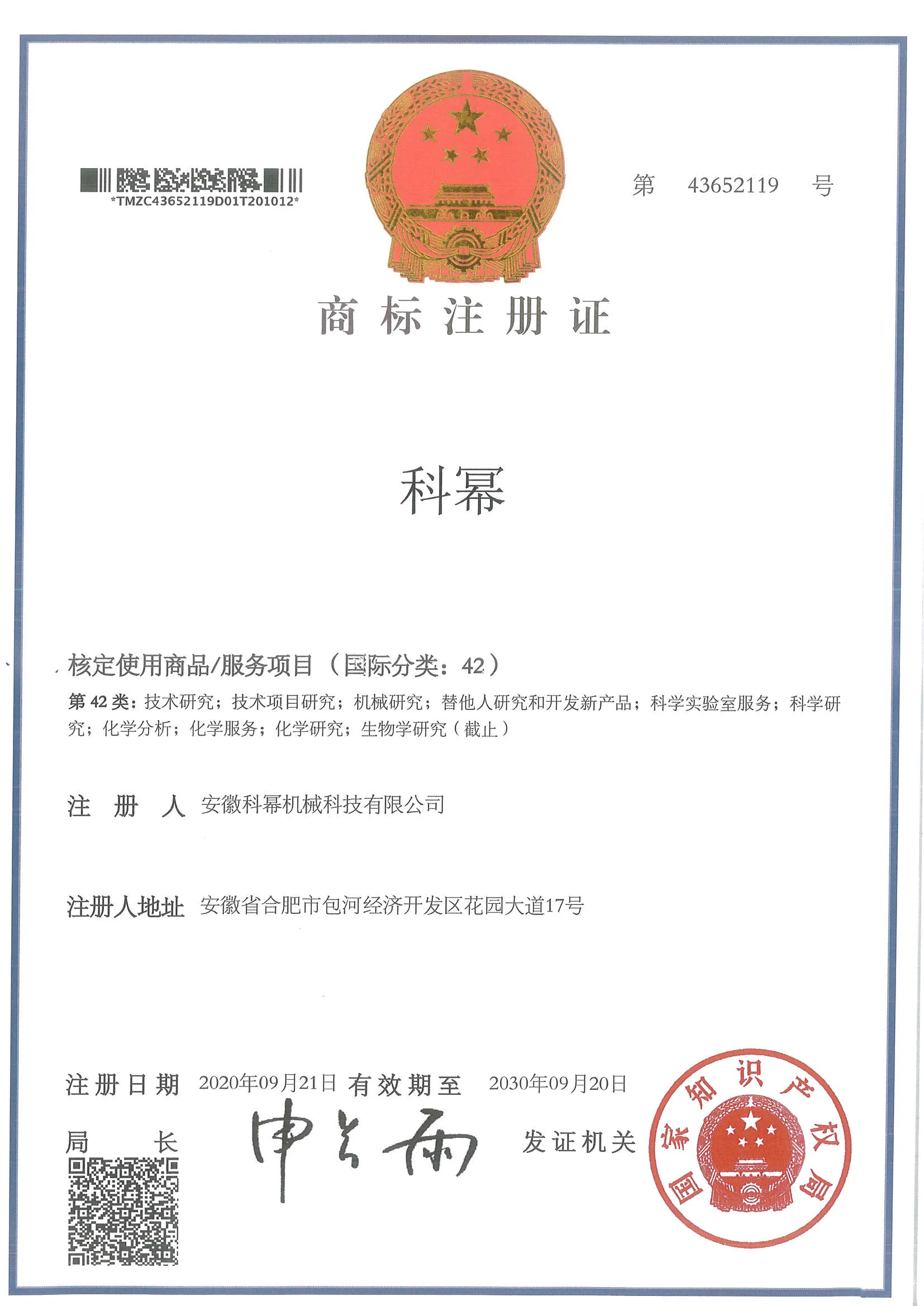

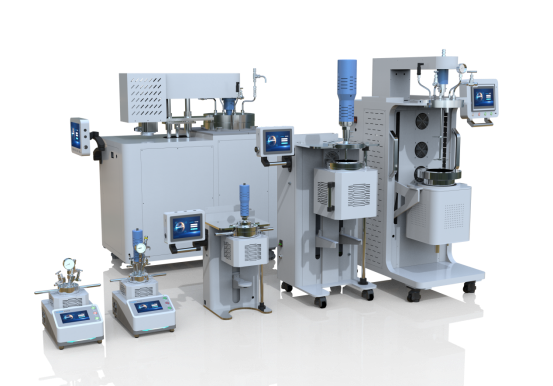

COMPANY INTRODUCTION

Anhui Kemi Instrument Co. Ltd was founded by a creative team from University of Science and Technology of China (USTC)in 2014, aiming to design and provide high-quality and customized synthesis equipment for global R&D users.We have SGS, ISO9001 and CE certificates. Our company is committed to design and provide “safe, convenient, accurate and efficient” equipment, and accelerate R&D progress with our professionalism and quality. Up to 2025, we have over 300 clients from over 35 countries, and our products have helped R&D users to publish over 900 papers in top-tier journals.

Factory and Package Overview

Application Field

High-temperature processing: Provides a high-temperature environment up to 1200°C.

Atmosphere control: Enables processing under vacuum, inert gases (Ar, N₂), reducing gases (H₂, CO), oxidizing gases (O₂, air), or mixed gas environments.

Precise temperature control: Achieves complex heating, holding, and cooling programs.

Small-batch/Experimental processing: Ideal for R&D, small-scale production, material screening, and quality control.

Therefore, it serves as an indispensable key piece of equipment in university and research institute laboratories, as well as in high-tech enterprises requiring new material development, process optimization, and quality control (e.g., materials, chemical, electronics, new energy, ceramics, etc.). Key factors to consider when selecting include furnace tube material (quartz, alumina, stainless steel, etc.), heating zone length, temperature control accuracy, maximum heating rate, atmosphere control precision, and safety considerations.

WHY CHOOSE US?

In a global marketplace filled with choices, we stand out as a reliable and innovative partner for your business needs. Our commitment to quality, efficiency, and customer satisfaction has made us the preferred choice for clients worldwide.

Adhere to strict international quality standards (ISO/CE certified). Each product undergoes 12 inspection processes to ensure zero defects.

With over 12 years in the industry, we’ve served 20000+ clients across 30+ countries, providing customized solutions for diverse needs.

Direct factory supply cuts out middlemen, offering you competitive prices with 10-15% savings compared to the market average.

Benefit from our efficient supply chain—80% of orders are delivered within 15 days, even for large volumes.

24/7 multilingual support (English, Spanish, Mandarin) and a dedicated account manager ensure seamless communication from inquiry to after-sales.

Our R&D team, consisting of 50+ experts, launches 10+ new products annually, keeping you ahead of market trends.

Contact us today for a free quote or personalized consultation. Let’s build a successful partnership together!

Precautions

-The positive pressure inside the furnace tube should not be higher than 0.02MPa.

-Due to the high pressure inside the cylinder, so the gas cylinder must be equipped with a reducing valve when the gas is introduced into the furnace tube, it is recommended to buy a pressure reducing valve in our company, the range of the pressure reducing valve of our company is 0.01MPa-0.1MPa, the use of which will be more accurate and safer.

-For sample heating experiments, it is not recommended to close the extraction valve and inlet valve at the flange end of the furnace tube. If it is necessary to close the air valve to heat the sample, you should always pay attention to the pressure gauge, if the air pressure is greater than 0.02MPa, you must immediately open the relief valve to prevent accidents (such as furnace tube rupture, flange flying out, etc.).

-The gas flow into the furnace tube needs to be less than 200SCCM(or 200ml/min).