Table of Contents

Selecting the right high-temperature furnace is crucial for achieving consistent and reliable results in various industrial and laboratory applications. The furnace you choose must align with your specific process requirements, from temperature capabilities to material compatibility. Here are the key factors to consider when selecting a high-temperature furnace to ensure optimal performance and longevity.

Temperature Requirements

Maximum Operating Temperature

The first step in choosing the right furnace is determining the maximum temperature your process requires. The furnace’s maximum rated temperature should be considerably higher (usually 100°C to 200°C) than your target operating temperature. This extra capacity ensures that the heating elements do not overheat, promoting durability and preventing premature failure.

Temperature Uniformity and Control

For many applications, maintaining a uniform temperature across the entire chamber is essential. Temperature fluctuations can compromise the quality of your results. Advanced control systems such as PID controllers and multi-segment programming are necessary to achieve precise control. Additionally, an efficient furnace design with proper insulation is key to minimizing temperature gradients and ensuring a stable hot zone.

Heating Rate

The rate at which the high temperature furnace heats up is another important consideration. If your process requires rapid heating, ensure that the furnace is designed with heating elements capable of achieving fast temperature rises. Different furnace designs, such as those using resistance wire or silicon carbide rods, offer varying heating rates based on your needs.

Material Compatibility and Atmosphere

Work Material

The materials being processed in the furnace (metals, ceramics, composites, etc.) dictate the atmosphere and temperature range required. For example, some metals require specific atmospheres to prevent oxidation or contamination, while others may demand higher temperatures.

Chamber/Lining Material

The internal components of the furnace, including refractory bricks and fiber insulation, must withstand the temperatures and chemical conditions of the process. Ensure that the furnace’s lining is compatible with the materials being processed and the intended atmosphere to prevent degradation or contamination.

Heating Element Material

The choice of heating element material plays a critical role in both temperature performance and material compatibility. Some commonly used heating element materials include:

- Resistance Wire (e.g., Nichrome, Kanthal): Suitable for air atmospheres and temperatures up to around 1200°C.

- Silicon Carbide (SiC) Rods: Ideal for temperatures ranging from 1600°C to 1700°C, and well-suited for oxidizing atmospheres.

- Molybdenum Disilicide (MoSi₂) Elements: Capable of reaching up to 1800°C to 1900°C, these elements perform well in oxidizing environments.

- Refractory Metals (e.g., Tungsten, Molybdenum): Used for extremely high temperatures (>2000°C) in vacuum or inert/reducing atmospheres.

Atmosphere Requirements

The furnace atmosphere can be critical to the success of your process. Different types of atmospheres include:

- Air (Oxidizing): Standard for muffle furnaces.

- Inert/Reducing (e.g., Argon, Nitrogen, Hydrogen): Requires gas-tight systems, such as tube or vacuum furnaces, to maintain the integrity of the environment.

- Vacuum: Certain processes, such as brazing or heat treatment of reactive metals, require a vacuum-tight chamber and a specialized pumping system.

Size and Capacity

Working Volume (Size)

The internal dimensions of the furnace, particularly the hot zone, must be large enough to accommodate your largest sample or batch. Adequate clearance is needed to ensure proper heat circulation, which is vital for uniform temperature distribution and process consistency.

Throughput/Capacity

In industrial applications, you may need to consider the type of furnace based on your throughput requirements. Batch furnaces are ideal for smaller, distinct loads, while continuous furnaces are designed for high-volume, automated processing, often found in large-scale manufacturing settings.

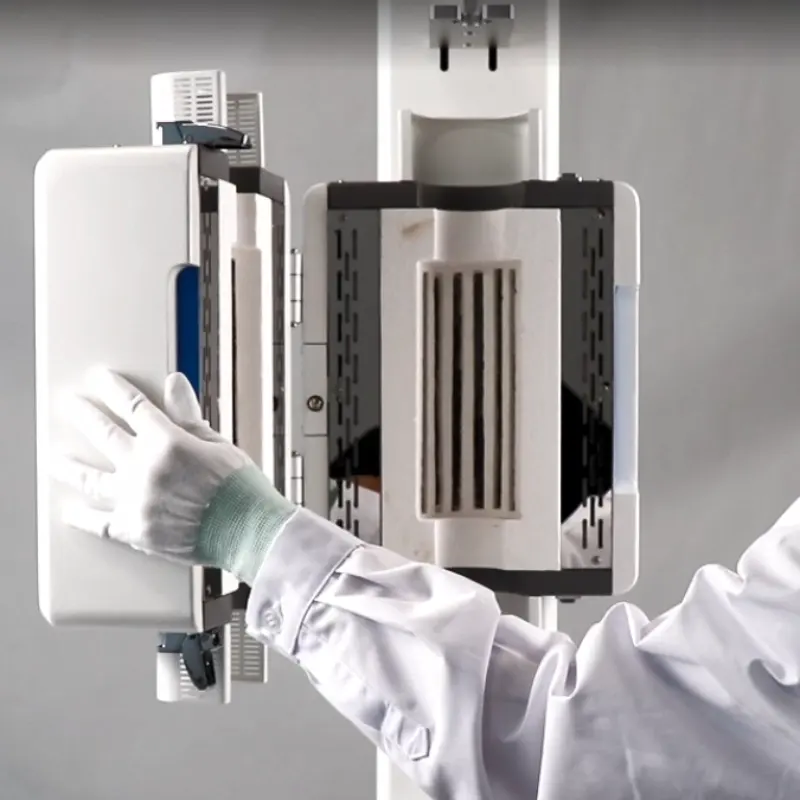

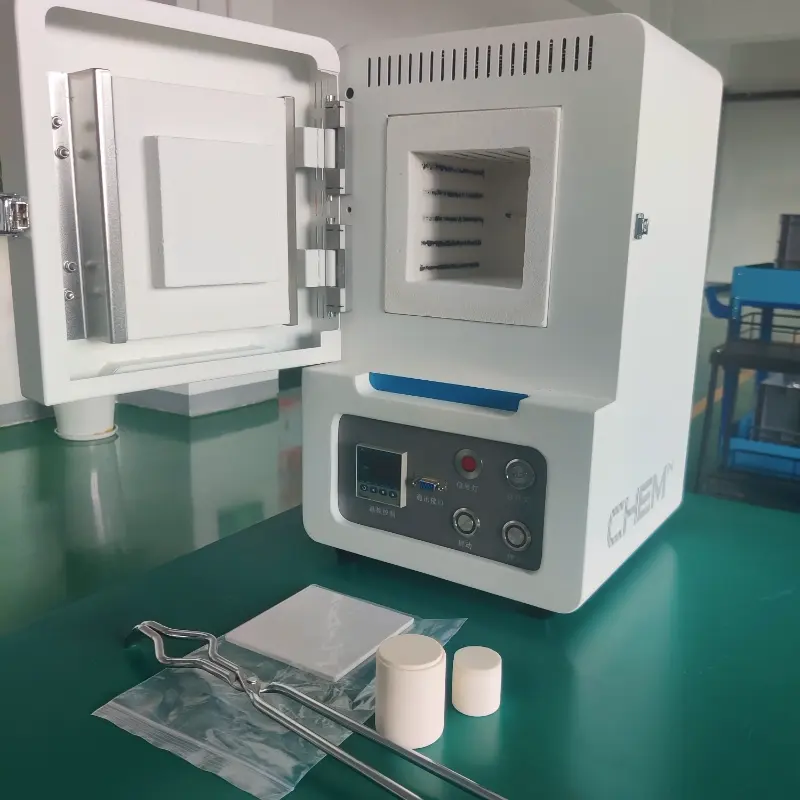

Furnace Type

The lab high temperature furnace design should be selected based on the specific application and process requirements. Common furnace types include:

- Box/Muffle Furnaces: Typically used for general laboratory applications and batch processing in air or mild atmospheres.

- Tube Furnaces: Excellent for small samples, controlled atmospheres (gas or vacuum), and processes that require a continuous flow of materials. These furnaces can be configured horizontally or vertically, depending on the process.

- Vacuum Furnaces: Ideal for high-purity processes, vacuum furnaces are used to prevent oxidation and are commonly employed in the heat treatment of reactive metals.

- Industrial Furnaces (e.g., Rotary Kiln, Electric Arc, Bogie Hearth): Designed for high-volume production in industries such as steel, cement, and ceramics.

Operational and Economic Factors

Energy Efficiency

A well-insulated furnace will significantly reduce long-term operational costs by improving energy efficiency. Look for furnaces that utilize advanced insulation materials, such as lightweight ceramic fiber, to minimize heat loss. High-efficiency heating elements also contribute to energy savings over time.

Cost Considerations

The total cost of ownership should be considered when evaluating a furnace. Beyond the initial purchase price and installation, consider ongoing expenses related to energy consumption, maintenance, and replacement costs for heating elements and insulation. While a more expensive furnace may have higher upfront costs, its longevity and energy efficiency can result in lower overall operational costs.

Safety Features

Given the high temperatures involved, safety is paramount. Ensure the furnace is equipped with critical safety features such as over-temperature protection, safety interlocks, and compliance with industry standards (e.g., AMS 2750 for aerospace). These features are vital for maintaining safe operation and preventing accidents.

Automation and Control

Modern high-temperature furnaces come equipped with sophisticated automation features, including programmable temperature profiles, data logging, and remote monitoring. These features enhance process repeatability and overall efficiency by enabling precise control over heating cycles and reducing the likelihood of human error.

Power Supply

Ensure that the furnace’s power requirements align with your facility’s power capabilities. Depending on the furnace type, you may need to verify whether the furnace operates on a single-phase or three-phase electrical supply and ensure that the required voltage is compatible with your system.

In conclusion, selecting a high-temperature furnace is a detailed and critical decision that requires careful consideration of various factors, from temperature requirements to operational efficiency and safety. By understanding your process needs and evaluating the furnace’s capabilities against these factors, you can ensure optimal performance and longevity, leading to improved results and cost savings in the long term.