Table of Contents

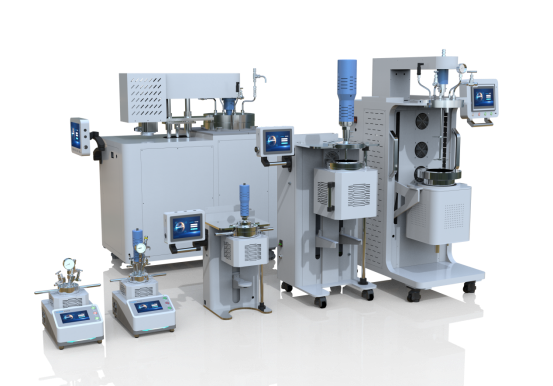

High-temperature autoclave reactors are core equipment widely used in industries such as chemical manufacturing, pharmaceuticals, and energy. Their primary function is to accelerate chemical reactions by providing a high-temperature and high-pressure environment. With technological advancements and broader applications, more customers are demanding higher operational efficiency, maintenance, and troubleshooting capabilities from these reactors. This article provides a detailed discussion on the principles of efficient operation, common faults and their remedies, cleaning requirements, and maintenance practices to ensure safe and stable long-term use.

Efficient Operation Of High-Temperature Autoclave Reactors

Efficient operation of a high-temperature high-pressure reactor relies on precise equipment design and strict operational procedures. To ensure stable operation and maximize reaction efficiency, all components, control systems, and process workflows must be properly designed and regulated.

Key Components and Configuration

high-temperature autoclave reactors are equipped with various safety and monitoring devices to ensure the reaction occurs within safe limits while improving reaction efficiency.

Key components include:

- Pressure measuring devices: Monitor the internal pressure of the reactor. By comparing measured pressure to preset safety limits, reaction conditions can be adjusted in time, or emergency measures can be triggered to prevent overpressure explosions.

- Temperature measuring devices: Accurately monitor internal temperatures to prevent runaway reactions or equipment damage. Multi-point temperature monitoring is often used to ensure uniform heating.

- Agitation system: Most reactors feature magnetic stirrers, capable of maintaining uniform mixing of reactants under extreme temperature and pressure. Magnetic stirring is contactless, reducing mechanical wear and avoiding leaks that can occur with traditional seals.

- Relief valves and safety valves: Prevent overpressure accidents by automatically releasing excess pressure during the reaction.

- Cooling system: Controls reaction temperatures, preventing overheating that could damage the equipment or reduce reaction efficiency.

Operating Procedures and Technical Requirements

Operating lab high-temperature autoclave reactor involves more than just temperature and pressure control. Material addition sequence, reaction time, and cooling procedures are critical.

Key requirements include:

- Temperature and pressure control: Heat the reactor gradually during start-up to avoid thermal stress and potential cracking. Once the set temperature is reached, maintain it precisely using the temperature control system.

- Material addition: Add reactants in a specific order and proportion to avoid incomplete reactions or undesired side reactions.

- Cooling and venting: After the reaction, cool the reactor first to gradually reduce pressure to atmospheric levels before releasing gases. Rapid depressurization can cause equipment damage or incomplete reactions.

Autoclave Reactor Common Faults and Troubleshooting

Long-term use of high-temperature autoclave reactors may result in common faults that affect stable operation. Timely detection and resolution are critical for efficient operation.

Valve leakage and bubbles

Symptoms: Leakage or bubbling at valves, causing unstable reaction conditions.

Causes: Damaged valve seals or gaskets.

Remedies: Inspect and replace seals or gaskets; if unresolved, contact the manufacturer’s service department for repair or valve replacement.

Seal surface leakage

Symptoms: Leakage at the reactor sealing surface, compromising the containment of gases and liquids.

Causes: Loose screws or worn seal surfaces.

Remedies: Tighten screws as needed; if the seal is damaged, regrind or replace it.

Magnet failure in magnetic coupling drives

Symptoms: Internal magnets fail to rotate, and motor current drops.

Causes: High temperature or poor cooling water circulation causes magnet demagnetization or expansion.

Remedies: Ensure proper cooling system flow; contact the service department for magnet replacement if damaged.

Bearing friction noise

Symptoms: Abnormal noise from the stirrer.

Causes: Worn bearing sleeves or bearings increasing friction.

Remedies: Inspect bearings and sleeves; replace worn parts with original specification components.

Autoclave Reactor Cleaning Guidelines

Lab high-temperature reactors often handle highly reactive substances, leaving significant residues. Regular cleaning is necessary to maintain efficiency.

Pre-Cleaning Preparation

Ensure the stirrer, heating, and electrical switches are turned off. Never clean at high temperatures.

Cleaning Steps:

1.Internal wall cleaning: Use mother liquor to clean the reactor walls, especially around the stirrer joint, to remove residual reactants.

2.Solvent cleaning: Add a suitable solvent through the vent valve and stir for 10 minutes to remove residues.

3.Special cleaning: For long-unused reactors, soak in anhydrous ethanol to maintain cleanliness and prevent contamination.

4.Cooling and venting: Cool first, then gradually release gas to avoid thermal shock damage.

Autoclave Reactor Design Requirements and Safety Measures

high-temperature autoclave reactors must meet strict safety standards, particularly in materials, temperature control, and sealing.

High temperature and corrosion resistance: Typically made of stainless steel or corrosion-resistant alloys to withstand extreme conditions.

Double-seal design: Main seals use double-line sealing; other sealing points employ precision contact surfaces with lubrication to ensure effectiveness.

Temperature uniformity: Multi-point temperature sensors monitor different zones to prevent uneven heating.

Regular calibration: Temperature and pressure sensors must be calibrated periodically to ensure accurate measurement.

Conclusion

High-temperature laboratory autoclave reactors are critical equipment in many industrial processes. Efficient and safe operation relies on precise design, strict procedures, and timely maintenance. Regular inspections, cleaning, and fault handling significantly improve efficiency and extend equipment life. Maintaining optimal conditions in high-temperature and high-pressure environments enhances production efficiency while ensuring safety.