Inhaltsverzeichnis

Was ist ein Hochtemperaturofen und warum ist er wichtig?

Ein Hochtemperaturofen ist ein unverzichtbares Gerät für viele Branchen und Labore, darunter die Metallurgie, Keramik, Pharmazie und Glasproduktion. Im Gegensatz zu Standardöfen arbeiten diese Öfen bei deutlich höheren Temperaturen, was für die Verbesserung und Bearbeitung der Eigenschaften verschiedener Materialien entscheidend ist. Ob in der Forschung oder Produktion – Hochtemperaturöfen sind unerlässlich, um eine präzise Temperaturregelung zu gewährleisten und die gewünschte Materialqualität zu erreichen.

Wie funktioniert ein Hochtemperaturofen?

Im Herzen eines Hochtemperaturofen ist die Umwandlung verschiedener Energiearten in Wärme, um die Materialien im Inneren zu erwärmen. So funktioniert es:

Elektrische Energie: Elektrische Energie kann auf verschiedene Weise in Wärme umgewandelt werden, unter anderem durch Widerstandserwärmung (mithilfe von Heizelementen wie Kanthal-Draht), Induktionserwärmung (mithilfe elektromagnetischer Felder) oder Strahlungserwärmung (wobei die Wärme durch Strahlung der Heizelemente übertragen wird).

Chemische Energie: Zur Wärmeerzeugung werden Brennstoffe wie Erdgas oder Kohle verbrannt und die Abgase sicher abgeleitet.

Sobald Wärme erzeugt wird, wird sie durch Strahlung, Konvektion und Wärmeleitung auf die Materialien im Ofen übertragen. Strahlung ist die primäre Methode der Wärmeübertragung, aber auch Konvektion und Wärmeleitung sind wichtig.

Hochtemperaturöfen – Schlüsselkomponenten und Funktionen

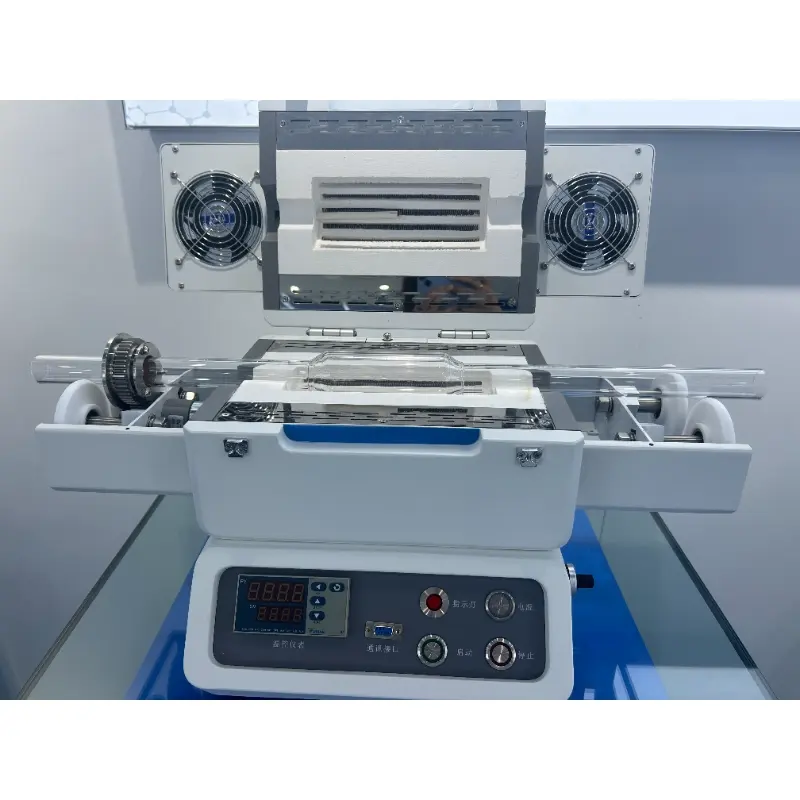

Hochtemperaturöfen bestehen aus mehreren wesentlichen Teilen:

Heizelemente: Diese Materialien, wie Kanthaldraht oder Siliziumkarbid, wandeln elektrische Energie in Wärme um.

Ofenkammer: Der Raum, in dem Materialien erhitzt werden, besteht oft aus hochtemperaturbeständiger Keramik, um die Probe von schädlichen Nebenprodukten zu trennen.

Isoliermaterialien: Diese Materialien, wie beispielsweise Aluminiumoxidfasern oder Schamottesteine, halten die Wärme im Inneren und verringern den Energieverlust.

Kontrollsystem: Verwendet Sensoren und intelligente Regler, um die richtige Temperatur aufrechtzuerhalten und sicherzustellen, dass die Heizung konstant bleibt.

Lufteinlass-/Auslassöffnungen: Hilft, ein stabiles Raumklima aufrechtzuerhalten, indem Feuchtigkeit oder Schadstoffe entfernt werden.

Außenschale: Aus Edelstahl gefertigt, um den Ofen vor Beschädigung und Korrosion zu schützen.

Zusammen sorgen diese Komponenten dafür, dass der Ofen effizient läuft, die erforderlichen Temperaturen erreicht und Abfall minimiert.

Auswahl der richtigen Materialien für Hochtemperaturöfen

Beim Entwurf einer hochwertiger Hochtemperaturofenist es wichtig, Materialien zu wählen, die extremer Hitze standhalten und gleichzeitig Haltbarkeit und Stabilität gewährleisten. Gängige Materialien sind:

Außenschale: Edelstahl oder kohlenstoffarmer Stahl bietet Festigkeit und Korrosionsbeständigkeit.

Heizzone: Materialien wie Keramiksteine oder Zirkonoxid halten die Wärme im Inneren und sind verschleißfest.

Heizelemente: Aufgrund ihrer thermischen Stabilität werden hochschmelzende Materialien wie Kanthaldraht, Siliziumkarbid und Platin verwendet.

| Komponenten | Häufig verwendete Materialien | Typische Temperaturbereiche (falls zutreffend) | Hauptmerkmale |

| Gehäuse | Kohlenstoffarmer Stahl (Pulverbeschichtung), Edelstahl (SS 304/316) | – | Langlebig, korrosionsbeständig, GMP-konform |

| Innerer Hohlraum | Keramiksteine, Zirkonoxidplatten, Ziegel mit hohem Aluminiumoxidgehalt, Aluminiumoxidkeramik, Quarzglas, Zirkoniumdiborid-Verbundkeramik | Keramikfliesen: bis 1200°C | Hitzebeständig, hervorragend isolierend, korrosionsbeständig, transparent (Quarzglas) |

| Zirkonoxidplatten: bis 1600°C | |||

| Hochtonerdefliesen: bis zu 1800 °C | |||

| Heizkörper | Kanthal-Draht, Siliziumkarbid (SiC), Molybdändisilizid (MoSi2), Wolframdisilizid (WSi2), Platin, reines Rhodium, Platin/Rhodium-Legierung, Wolfram, Molybdän, Eisen-Chrom-Aluminium/Nickel-Chrom-Legierung | Kanthal/SiC: typischerweise 1000–1800 °C | Hoher Schmelzpunkt, Oxidationsbeständigkeit, thermische Stabilität, hohe Wärmeleitfähigkeit (SiC) |

| Platin: 1450–1600 °C | / | ||

| Reines Rhodium: bis 1960°C | |||

| Molybdän: bis 1900°C | |||

| Wolfram: bis 2500°C | |||

| Isoliermaterial | Vakuumgeformte hochreine Aluminiumoxidfasern, hochwertige Isolierfaserblöcke, leichte Feuerfeststeine | – | Hervorragende Wärmedämmung, geringes Gewicht, energiesparend |

Sicherer und effizienter Betrieb von Hochtemperaturöfen

Die Arbeit mit Hochtemperaturöfen birgt Risiken wie Verbrennungen, Stromschläge oder sogar Explosionen. Daher sind strenge Sicherheitsvorschriften unerlässlich.

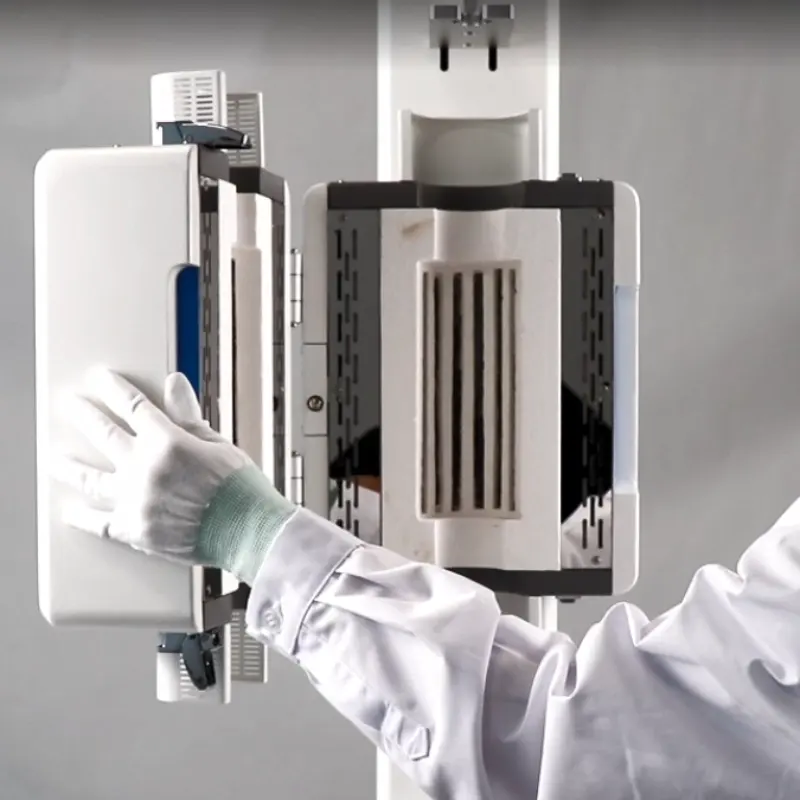

Persönliche Schutzausrüstung (PSA): Bediener sollten Handschuhe, Schutzbrille, Laborkittel und Gesichtsschutz tragen. Bei höheren Temperaturen werden hitzebeständige Jacken und Schuhe empfohlen.

Hochtemperaturöfen Sicherheitstipps:

- Betreiben Sie den Ofen niemals alleine, insbesondere wenn er unbeaufsichtigt ist.

- Stellen Sie sicher, dass der Ofen ordnungsgemäß geerdet ist.

- Schalten Sie immer den Strom aus, bevor Sie den Ofen überprüfen oder daran arbeiten.

- Öffnen Sie die Ofentür erst, wenn der Ofen vollständig abgekühlt ist.

- Verwenden Sie zum Umgang mit heißen Materialien Hochtemperaturzangen.

- Sorgen Sie für eine gute Belüftung, um eine Gasansammlung zu verhindern.

Notfallmaßnahmen: Bediener sollten in Sicherheitsmaßnahmen geschult sein. Im Brandfall ist die persönliche Sicherheit oberstes Gebot. Benutzen Sie einen Feuerlöscher oder rufen Sie Hilfe.

Aufrechterhaltung der Leistung von Hochtemperaturöfen

Um einen Hochtemperaturofen in Topform zu halten und Probleme wie ungleichmäßiges Heizen oder verringerte Effizienz zu vermeiden, ist regelmäßige Wartung von entscheidender Bedeutung.

Wartungscheckliste:

Täglich: Überprüfen Sie das Bedienfeld, die Gasleitungen und die elektrischen Anschlüsse auf Probleme.

Monatlich: Überprüfen Sie Heizelemente auf Verschleiß, reinigen Sie Lüfter und kalibrieren Sie Sensoren.

Vierteljährlich: Reinigen Sie den Innenraum und überprüfen Sie die Sicherheitsschalter.

Jährlich: Führen Sie eine vollständige Inspektion durch und ersetzen Sie verschlissene Teile.

Wenn Sie diese Schritte befolgen, stellen Sie sicher, dass der Ofen reibungslos funktioniert und länger hält.

Öfen Fehlerbehebung bei häufigen Problemen

Bei Hochtemperaturöfen können Probleme wie ungleichmäßige Erwärmung, Steuerungsfehler oder ungewöhnliche Geräusche auftreten. So beheben Sie diese Probleme:

Häufige Probleme und Lösungen bei Hochtemperaturöfen:

Ungleichmäßige Erwärmung: Dies kann an verschlissenen Heizelementen oder einer schlechten Luftzirkulation liegen. Überprüfen und ersetzen Sie beschädigte Teile.

Überhitzung: Überschreitet der Ofen die eingestellte Temperatur, kann dies an einem defekten Thermostat oder einem verstopften Abzug liegen. Reinigen oder ersetzen Sie die erforderlichen Komponenten.

Probleme mit der Temperaturregelung: Wenn die Temperaturregelung nicht funktioniert, kann dies an defekten Sensoren oder elektrischen Problemen liegen. Regelmäßige Kontrollen und Kalibrierungen können dies verhindern.

Verlängerung der Lebensdauer des Ofens

Damit der Ofen jahrelang reibungslos läuft, gibt es folgende Strategien:

Hochtemperaturöfen – Schlüsselstrategien:

- Regelmäßige Reinigung: Entfernen Sie Staub und Ablagerungen im Inneren des Ofens.

- Rechtzeitiger Teileaustausch: Warten Sie nicht, bis Teile kaputt gehen. Ersetzen Sie sie, bevor sie größere Probleme verursachen.

- Vorausschauende Wartung: Nutzen Sie Daten aus dem Ofen, um potenzielle Probleme vorherzusagen und frühzeitig zu beheben.

- Schmierung: Schmieren Sie bewegliche Teile, um Verschleiß vorzubeugen.

- Dokumentation: Behalten Sie den Überblick über Reparaturen und Austausch, um den Zustand des Ofens stets im Blick zu behalten.

Wenn Sie diese Strategien befolgen, tragen Sie dazu bei, dass Ihr Ofen in einem hervorragenden Zustand bleibt und kostspielige Ausfallzeiten vermieden werden.

Abschluss

Hochtemperaturöfen sind sowohl in der Industrie als auch in der Forschung unverzichtbar. Dank ihrer Fähigkeit, extremen Temperaturen standzuhalten, spielen sie eine entscheidende Rolle – von der Fertigung bis hin zu wissenschaftlichen Durchbrüchen. Mit dem technologischen Fortschritt verbessern sich Design und Sicherheitsmerkmale dieser Öfen, was sie noch zuverlässiger macht. Sorgfältige Wartung und Sicherheitsprotokolle tragen dazu bei, dass diese Öfen auch in den kommenden Jahren ihre Leistung erbringen. Mit der Entwicklung neuer Materialien und Verfahren werden Hochtemperaturöfen auch weiterhin ein Schlüsselfaktor für Innovationen sein.