Table of Contents

For industries ranging from semiconductor manufacturing to advanced materials research, the precision of gas atmospheres is not just a detail—it is the variable that defines success or failure. Whether you are conducting Chemical Vapor Deposition (CVD) or calibrating sensitive analyzers, the traditional method of buying pre-mixed gas cylinders is becoming obsolete. It is costly, logistically heavy, and inflexible.

The modern solution lies in Gas Distribution Mixing Systems—on-demand units that blend pure gases with high accuracy. However, sourcing these systems from the global market requires a keen eye for technical specifications.

The Core: Mass Flow Control (MFC) Technology

At the heart of any gas mixer is the Mass Flow Controller (MFC). Unlike volumetric flow meters, which are affected by temperature and pressure changes, MFCs measure the actual mass of the gas molecule, ensuring stability.

When evaluating a supplier, look beyond the basic flow rate. Pay attention to Precision and Range.

Accuracy Standards: A reliable industrial standard for gas mixing is typically ±1.5% F.S. (Full Scale). This level of precision ensures that your mixture ratios remain consistent batch after batch.

Flexibility: Top-tier manufacturers offer selectable ranges (e.g., 100sccm to 500sccm) calibrated to specific gases like Nitrogen (N2), allowing a single device to handle multiple experimental protocols.

Material Science: Why “Stainless Steel” Isn’t Enough

Gas distribution often involves reactive or corrosive gases. Standard piping can degrade over time, introducing particulate contamination into your process.

High-quality manufacturers distinguish themselves by the materials they use. Do not settle for generic tubing. Look for systems that utilize SS316L or Duplex Stainless Steel for all wetted paths.

The Advantage: Duplex stainless steel offers superior strength and corrosion resistance compared to standard 304 stainless steel.

Fittings: Ensure the system uses precision double-ferrule fittings. These provide a leak-tight seal essential for maintaining pressure stability (typically operating between 0.1 to 0.5 MPa) and safety in laboratory environments.

Automation and Integration Capability

In the era of Industry 4.0, a gas mixer should not be an isolated island. It must integrate seamlessly with other equipment.

Modern buyers demand Touch Screen Control (HMI). A digital interface allows users to input mixing ratios directly, monitor real-time flow data, and adjust parameters without manual valve turning. Furthermore, check if the system can operate in conjunction with downstream equipment, such as Tube Furnaces or reactors. This linkage allows for automated “recipe” creation, where gas flows change automatically as the furnace ramps up temperature, a critical feature for material synthesis.

The “Direct Factory” Advantage

Finally, consider the source. Many “brands” on the market are simply re-sellers. working directly with a source factory (Original Equipment Manufacturer) offers two distinct advantages:

Customization: Factories can modify channel numbers (e.g., 2-channel vs. 4-channel), pressure ratings, and cabinet dimensions to fit specific benchtop spaces.

Cost Efficiency: Direct sourcing eliminates the middleman markup, often saving buyers 10-15% while providing direct access to technical R&D teams for troubleshooting.

Manufacturer Recommendation

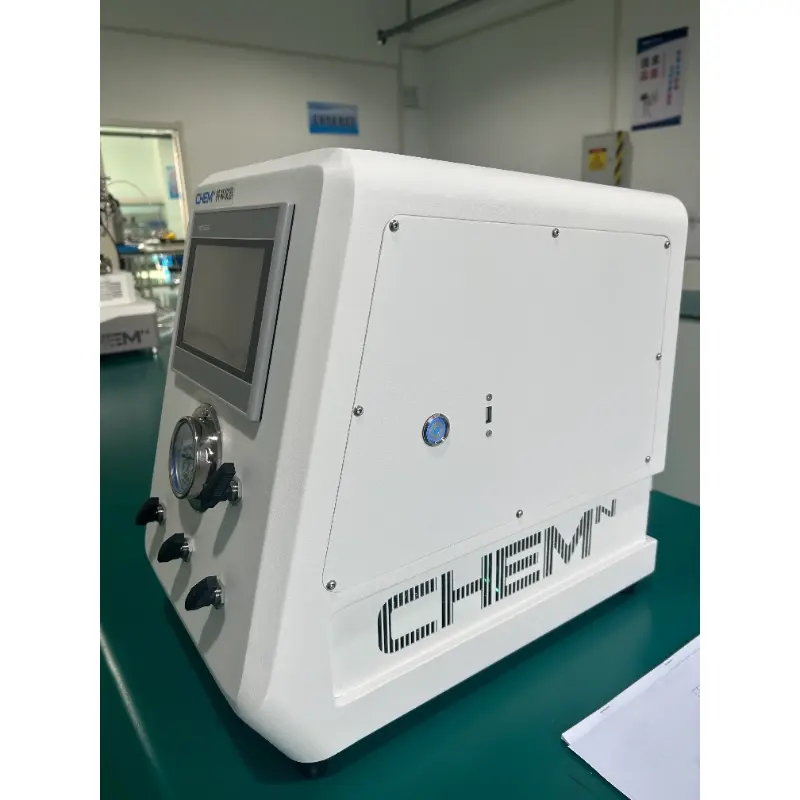

If you are looking for a partner that embodies these standards—combining high-precision MFC technology with robust factory-direct support—we recommend exploring Anhui Kemi Instrument Co., Ltd. (Kemi Lab Reactor).

Kemi is a specialized manufacturer founded by a research team from the University of Science and Technology of China (USTC). Their GD Series Gas Distribution Mixing Systems are designed specifically for high-demand laboratory and industrial applications.

Why consider Kemi’s Gas Mixers?

Robust Build: They utilize Duplex Stainless Steel tubing and SS316L needle valves, ensuring long-term durability against corrosion.

Smart Integration: Their systems feature intuitive touch-screen controls and are engineered to work perfectly alongside their renowned Tube Furnaces and High-Pressure Reactors.

Proven Precision: Standard precision is calibrated to ±1.5% FS, with customizable flow ranges (100sccm – 500sccm) to meet diverse experimental needs.

Global Reach: With products already serving over 300 clients in 35+ countries, Kemi offers the reliability of a global supplier with the flexibility and pricing of a direct factory. For customized gas mixing solutions that fit your specific lab reactor setup, visit their product page to view full technical specs.